This

accurate drawing

has been prepared by

Julian Wooldridge after

checking my pics and

swapping a few emails

....many thanks

Julian...this is extremely

helpful and may save

a few broken valves

and hearts.

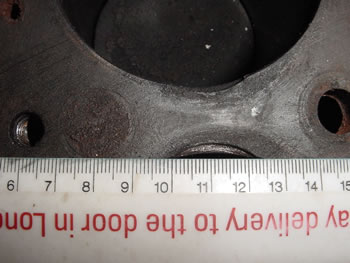

Exhaust Valve Cutouts

for MGB blocks

When

18v cylinder heads or modified cylinder heads are fitted

to non-18v blocks there is a danger of the exhaust valves hitting the

top of the block when the valve is at full lift. This applies to both

standard and modified lift camshafts.

To overcome this problem cutouts are needed in the block. The easiest

way of machining the cutouts is to use a half-round hand file ( not too

rough a cut on the file please!).

Prepare a cylinder head for marking out the position of the exhaust valves

by stripping all the valves from the head, leaving the exhaust valves (held

in

place with an elastic band on each valve). Apply some dark coloured felt-tip

pen or engineers blue to the top of the block around the bores.With the head

studs fitted to the block, lower the cylinder head into place (you don't need

to fit a head gasket for this job). Push an exhaust valve down till it contacts

the block, rotate the valve to mark the top of the block. Repeat this

operation for each of the exhaust valves.

Remove

the cylinder head and inspect

the cutouts, if you can't see them......

do them again!

Using the half-round file carefully file

the block to a depth of around 3mm

or 1/8th" and to the edge of the valve

plus 1mm or 40 thou.

Recheck the valve to block clearance

again by lifting the exhaust valve to

cam lift plus 2mm / 80 thou.

The accompanying photographs show

the shape and dimensions of the standard

cutout in an 18v block.