Technical Articles (during lockdown)

Installing relays

into older classic cars

Why do enthusiasts fit

relays in their cars?

Well possibly for a couple of reasons, but the most benefit would be derived from modifying the headlight circuit. The benefits hopefully when relays are fitted to this circuit will be that the headlights will be substantially brighter. Could that be true? Well with a little testing the answer ought to be evident, after which we can look at how to fit the relays if required.

Besides benefits to the

lighting circuit of brighter lights there is another benefit to fitting relays

in other circuits. When switches are operated, especially in higher powered DC

circuits, a flash can occur across the contacts of the switch. After a time this

flashing (normally referred to as arcing) will cause severe burning to the

switch contacts, causing poor operation and finally a complete failure of the

switch. When relays are fitted into a circuit the power through the switch is

drastically reduced and so arcing is suppressed and the switch will last far

longer. This of course is beneficial to the headlamp switch, the dipswitch in

the lighting circuit and also other switches such as the brake light switch all

of which can be protected with the use of relays.

How does fitting relays protect switches? Well if the

switch on the dashboard is only required to switch the load of the relay instead

of the load created by the headlamps then the current flowing through the switch

will be greatly reduced and the switch ought to be far more reliable. Let me

point out at this point I am pretty sure that the vast majority of the dashboard

switches on our cars are more than adequate for the job they do but I am simply

describing the suggested benefits of relays. It can be pointed out that in

modern cars most circuits are operated via relays so they must be better? Well

of course that is true however in modern cars the relays perform other

functions. They actually perform functions that we refer to as logic such as a

number of different ways to operate a circuit over and above a simple switch. On

top of this you will notice that modern dashboard switches are far smaller than

the large toggle switches we find in older cars, the use of these smaller

lighter switches is only made possible by the use of numerous relays.

OK so that seems

straightforward enough but if the headlights glow brighter with increased

voltage, then they will also glow significantly dimmer were the voltage to

reduce. What then could be the reasons why this voltage maybe reduced? If the

light bulb was connected directly across the battery then it would be as bright

as possible. However the light bulb is not connected directly across the battery

but is actually installed at the front of the car. It is then connected to the

battery by a circuit that contains a lighting switch, a dip switch and numerous

connections (bullets). Each one of these switches and connections could reduce

the voltage applied to the headlight bulbs due to poor connections leading to

high resistance and reduced voltage.

Whilst my car is well modified in plenty of other areas I

still make use of the original dip switch on the column and part of the original

harness from just under the scuttle to the front of the car where there is all

the original bullet connectors connecting wires to both headlamps. I decided to

do some testing to assess any problems with my headlamp circuits and began by

switching on the headlights, I then measured the voltage from the battery

positive to the negative (body) (This demonstrates how much voltage is

available). I then measured the voltage at a point in the front of the car where

the original bullet connector splits the feed to both headlamps, if everything

was working fine this ought to be the same value as the battery. However I was

staggered the difference was more than 1 volt and was nearer 1.5 volts (that is

more than a 10% reduction). I used a prong on my meter to poke into the bullet

to make a connection to the meter as it is absolutely essential to have the

lights switched on and operating to do this test. If the lights were to be

disconnected to do the test and the measurement made then there would be

absolutely no difference between the 2 readings and the test would be a waste of

time. After doing the voltage reduction test I decided to do another test to be

sure the readings were accurate. This time I connected a piece of wire to the

battery positive, the other end of the wire I connected into the bullet where I

had previously measured the reduced voltage. As I pushed it in and out of the

bullet a very noticeable increase and decrease in brilliance of the headlight

was easy to see, proving that voltage had reduced in the original circuit

causing a dimmer performance of the headlights.

So where was the point of high resistance that was

potentially causing my dim headlamps? Well to determine where the voltage is

being lost sounds an easy task but is quite difficult in practice. What we need

to do is to do the test described above at all connection points within the

circuit remembering that the lights have to be switched on whilst doing the

test. That means we need to access various switches and connections, many hidden

behind the dashboard or tucked into the steering column. I managed to do most of

them and I found out where my headlamp circuit was losing voltage and it was in

one place only. The voltage was disappearing across the “dipswitch” which of

course is located as a switch on the steering column. Those of you who are

familiar with these switches will of course not be surprised by this loss and

would probably have guessed that it would indeed be the problem area. I suppose

I could have purchased a new switch but considering popular opinion on the

quality of these items it is far easier and far cheaper to regain maximum

headlamp brilliance by simply fitting relays.

What is a Relay

The relay consists of 2 circuits and therefore generally

has 4 connections. The first circuit is known as the coil and it is the circuit

that will be operated by the original switch. Within the relay this coil when

energised (powered) becomes magnetic and attracts a metal former towards the

core. This is connected to a contact in circuit 2 and therefore when this occurs

the 2 connections on circuit 2 join together and will operate/power/switch

whatever is connected to them and thus replicate the action of the original

switch.

With reference to the photo of a relay it can be noted

that 4 connections can be seen on the base. On inspection it can also be noted

that most relays will have each of these connection numbered, these numbers are

almost always the same and so will dictate how the relay should be connected.

However what is not the same on all relays is the physical arrangement of the

connections and so reference to the connection numbers is always necessary to

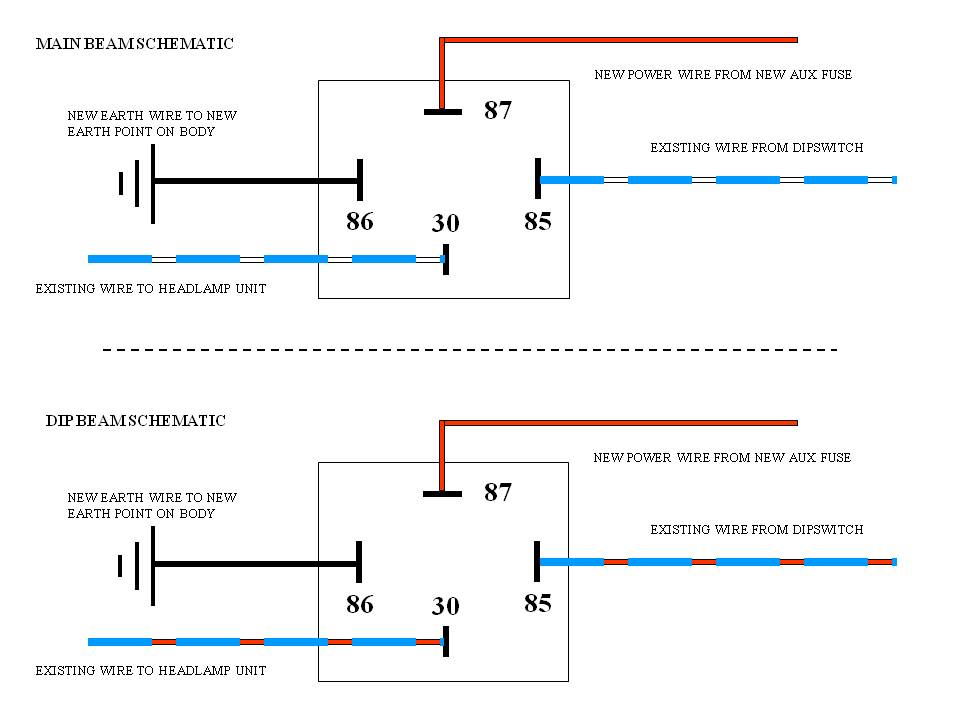

ensure correct connection and operation. The numbering system is easy with the

coil being on connections 85 and 86, whilst the contact is on connections 30 and

87. A very cheap supply for these relays is for you to take a trip to a scrap

yard and you will find under the bonnet of all modern cars a fuse box that will

contain a number of relays. These can be pulled out of the base of the fuse box

and can be used for our modifications.

Fitting relays

To change the lighting circuit to relay operation

requires 2 relays, one for the main beam circuit and the other for the dip beam

circuit. First let’s concentrate on the main beam circuit. In both modified

circuits we use the original wiring to operate the coil of the relay this on pin

85 with pin 86 now connected to earth. The original main beam wiring is coloured

Blue with white tracer from the dip switch to the main beam headlight. This has

to be connected to pin 85 on the relay so it either needs cutting at some point

to make the connection or perhaps disconnected from the headlight and routed

back. On my car I mounted the relays on my inner wing about halfway between the

switch and the actual headlight. I stripped back the loom insulation and found

the blue wire with the white tracer. Cutting the wire here I then needed to

extend each cut end to make it long enough to connect to the relay on the inner

wing. Looking in my spares/rubbish draws I found some blue wire with white

tracer that I could use to make the connections, so for me I simply connected

the extra wire to the relay terminals with soldered female spades and these

wires were then soldered onto the cut wire in the existing loom. To insulate

these new soldered connections I used heat shrink that makes a reasonably neat

job and then re wrap the loom with a few turns of tape. So the connections on

the new relay need to be connected these need the blue wire with the white

tracer connected to pin 85, pin 86 to a new wire connected to the body earth, a

new power wire to be connected to pin 87. This I ran from an always live

connection on my fuse box alternatively this could be connected to the battery

and an inline fuse used for protection. Then finally a connection from pin 30

requires connection to the original Blue wire with white tracer that connected

to the headlight unit.

So to recap the existing blue/white wire was cut in the

loom and a new piece was soldered to it and connected to pin 85 on the relay

base with a soldered female spade. From pin 30 another new piece of wiring is

then soldered onto the other cut piece of wire in the loom that is connected to

the headlight. To finish the wiring

installation a new live wire is connected to a new always live fuse and

connected to pin 87 and finally the new earth wire is connected to pin 86 and

the car body earth.

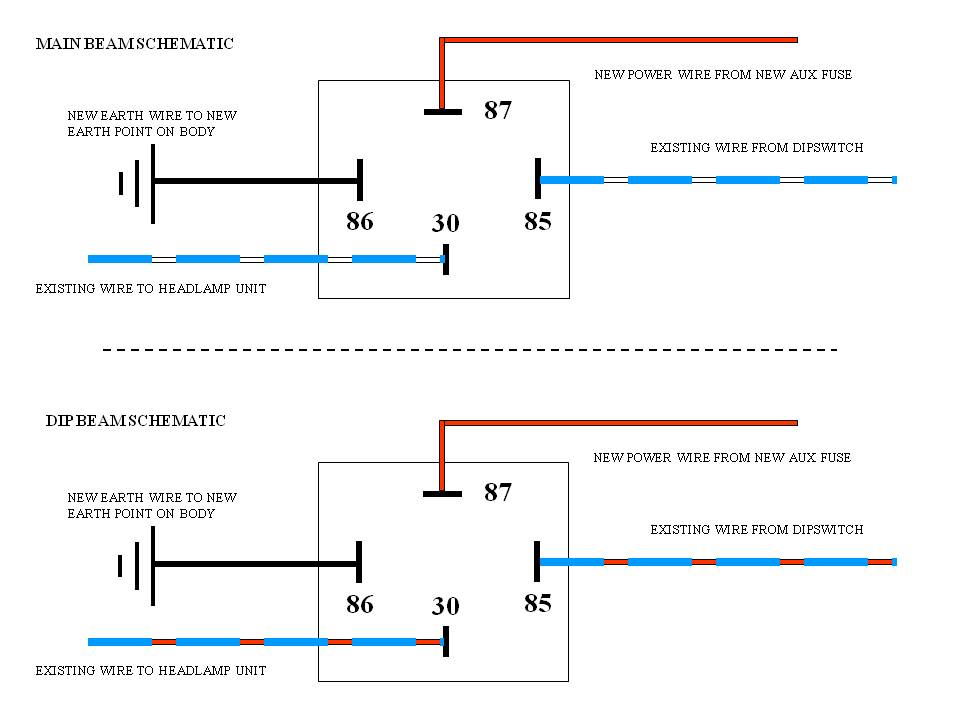

This effectively completes the

wiring for the Main beam and now the dip beam can be modified. This is very

similar to the modification of the main beam circuit except instead of working

on the blue with white tracer wiring simply substitute blue with red tracer. The

new power wire that was installed from a new always live fuse can be split near

the 2 relays and used to power both circuits. The source of this new supply

should be from an always live fuse in the fuse box or better still connect a new

wire to the battery cable (probably best fitted at the starter solenoid) then

through a new inline fuse before connecting to the relays.

The connections I make with the

spade connections on the relay I always do with a soldered connection. I find

the mechanically crimped connections very poor and to make these a quality

soldered joint is very easy. Instead of crimping these simply solder the wire

into the crimp and then I use a short piece of shrink wrap to insulate the spade

terminal.

This work I did on my Midget,

however fitting relays is very similar on all of our models. The colours on the

Midget are typical Lucas colours and are the same as many vehicles of the era.

However what ever vehicle you intend to modify it is important to make sure of

the relevant colours of the wiring before commencing the task.

Finally this technique can be

used to modify any such circuit in the very same manner as the headlights. As an

example if you wanted to protect the brake light switch with a relay then simply

find the green wire with a purple tracer and modify it exactly as you have done

to the headlight circuit.

Replacing the metal

coolant pipes on an MGTF –

Robert Taylor

The MGF and MGTF are renowned

for overheating issues and one of the reasons is that the volume of coolant is

small especially as it has to be piped from the rear engine to the front mounted

radiator and back again. A key part of this process is the approx. 2m long metal

coolant pipes that run under the car. These pipes are prone to rusting

and, as stainless steel replacements are

readily available, I decided to tackle the replacement. It is easy to get an air

lock in the coolant system so before tackling the work ensure that you are aware

of the correct bleeding procedure as explained later.

I first of all raised the car front and back using ramps

and axle stands. Set the heater controls to maximum so as to drain all or most

of the coolant which will later be replaced with fresh coolant. Remove the

expansion tank filler cap. There is no drain plug so release one of the hose

clips on the metal coolant pipe and allow the coolant to drain into a container.

There is a thick underfloor strengthening plate secured with approx. 24 bolts (see photo1).

.jpg) Photo 1 |

Photo 2 |

Photo 3 |

Photo 4 |

Photo 5 |

Photo 6 |

Photo 7 |

||

This needs to be removed to gain access to the metal

coolant pipes. Next, cut the cable ties that secure the main feed cable from the

battery that runs the length of the underside. Having allowed the coolant to

drain the other hose clips can be released and moved back on the rubber hoses. I

purchased replacement jubilee type hose clips in case they were needed but in

fact the original spring type hose clips were serviceable and retained for

originality. It is now possible to undo the 3 retaining bolts and remove the

metal coolant pipes (see photo2). The cooling system can now be flushed with

clear water and the radiator reverse flushed.

New cable ties were supplied

with the stainless steel coolant pipes but check before fitting that when the

main feed cable from the battery is cable tied in place there are no sharp edges

likely to cut into the cable. I filed down some sharp edges before fitting. The

new coolant pipe can be bolted into place, the rubber hoses fitted and secured

with the hose clips and the underfloor strengthening plate refitted. Ensure all

the bolts are replaced and correctly tightened as this is a structural item

evidenced by the number of bolts used.

See Photos 3 and 4 showing the front and rear

connections to the rubber hoses. It goes without saying that the rubber hoses

should be checked for condition and replaced if necessary at the same time.

However, the hoses on my 2005 TF were in good pliable condition with no sign of

cracking.

The recommended antifreeze is ethylene glycol based

containing OAT corrosion inhibitors which is pink in colour. The amount required

is 5.25 litres and a concentration of 50% is required to ensure the

anti-corrosion properties are maintained and not above 60% as cooling

efficiencies will be impaired.

It is important to follow the correct re-filling and

bleeding procedure otherwise an air lock could occur resulting to overheating.

1.

Turn the heater control to

max heat.

2.

Remove the bleed screw from

the top of the radiator (see photo 5)

3.

Open the heater bleed screw

(see photo 6) found behind the black plastic cover at the

rear of the front storage compartment.

4.

Fill the system from the

expansion tank taking care to keep the expansion tank full to prevent air

entering the system.

5.

When a constant flow of

coolant is being emitted from both bleed points close the radiator bleed screw

and then the heater bleed screw.

6.

Ensure the expansion tank is

topped up, fit the cap and run the engine until the engine reaches full

operating temperature. (Note: Do not operate the air conditioning if fitted.)

7.

Check the cooling system for

leaks and that the heater is emitting heat. If the heater is not emitting heat

there may be an air lock and the “Additional bleed” procedure should be

undertaken.

8.

This involves removing the engine compartment access panel, releasing the clip

and removing the inlet air hose from the throttle housing. This gives access to

the additional bleed screw on the radiator return valve.

I suggest taking the car for a short test run to ensure

the cooling system is working correctly before embarking on a journey.

Whilst I had the black plastic cover removed in the

front storage compartment I took the opportunity to remove the screen washer

bottle and give it a thorough clean out to prevent future blockages of the

screen washer jets. A minor maintenance task that saves much frustration if

overlooked.