Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

Remove distributor cap & withdraw the long rotary arm, taking care not to loose the carbon brush & spring.

Remove distributor cap & withdraw the long rotary arm, taking care not to loose the carbon brush & spring.

Remove the drive coupling & key from main shaft.

Remove alloy cover (2 screws), slip ring brush holder (2 screws), place carbon brush & spring in a safe place, discarding brush holder.

Lift off main magnet.

Remove the following, points cover, points slip ring, points center retaining bolt, points assembly, taking care not to loose carbon brush & spring from rear.

Remove both long hexagon nut/clips & screw from bass bearing housing, withdraw housing, taking care not to disturb ballrace.

IMPORTANT, a timing identification mark should now be painted or scribed onto both the fibre & steel gears to assist when reassembling the magneto.

The upper fibre gear may now be withdrawn. Withdraw the main armaturr - from the magneto body, taking care not to disturb the end ball race.

Wrap a short length of pvc tape around both ball races to protect them.

Scribe or paint a line along the length of the body of the armature to assist location when re-assembling. Remove the two long steel bolts holding armature together & separate with care both ends from center winding frame.

Now cut away all windings from core frame.

The built in condenser must now be carefully removed bit by bit from its housing in the gear end of the armature, taking care not to disturb the points securing brass strip & points holding nuts at the inner base of the condenser.

Clean & reassemble the three sections of the armature in their marked position, taking care when tightening the long screws.

Re-pack the bearings with grease, but no more than one third full please.

Re-fit the fibre timing gear taking care to re-align marks on both gears.

Refit bearing housing complete with any shims if fitted, replace screw & noting that the longest retaining nut with its shortest clip spring fits at the bottom position.

Tighten nuts & screw evenly & check for free running of shaft after fitting of drive coupling.

Slide in outer points slip ring, check that points are clean.

Refit points holder, taking care that carbon brush & spring are fitted to rear.

Check points gap, (0.012 inc).

Slide main magnet back into place & retain with alloy end cover & 2 screws.

A modern coil condenser to match the coil should now be secured via a suitable mounting tag to the cam ring clamp bolt.

The condenser wire together with a length of wire sufficient to reach the coil negative terminal should now be wired into the contact breaker cover terminal & the cover refitted.

The magneto may now be refitted to its correct timing marks.

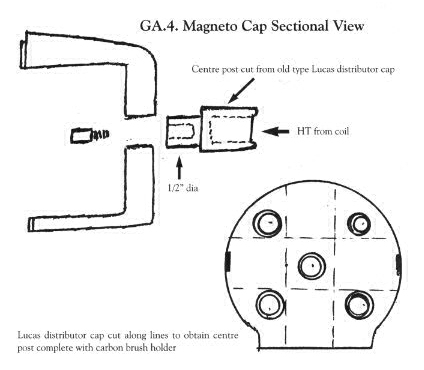

Now to modify the distributor cap. Using the centre dimple on the outside of the distributor cap as a guide drill right through the cap enter with a 1/4 die drill, then open up this hole to 1/2 inc.

Obtain from a car breakers yard a non ballasted 12volt coil with matching condenser, also a 4 cylinder distributor cap of the type with five HT terminals sticking upright.

Carefully with a small hacksaw cut away the outer four terminal posts until you are left with just the centre terminal post complete with its carbon brush holder.

Place this terminal post in a lathe with the carbon brush holder outermost & turn down the brush holder end to 1/2 inc die & just sufficiently long for the inner end to be flush with the inside face of the cap, (see diagram), in actual fact I turned my terminal post down in a pillar drill with the aid of a carefully held file.

The brush holder should be a push fit into the into place with Araldite.

Refit long rotary arm & its brush.

Fit carbon brush & spring to inside of cap & refit cap.

Wire up coil having mounted it in a convenient position, switch on & hope you have got it OK.

With a coil system fitted I have found it practical to reset the plug points to 25 thou resulting in quicker starting noticeable less use of the choke.

Hopefully, I should also get a few more miles to the sip of the expensive pollutant.

It may be my imagination, but I think the engine runs smoother with the coil, although in fairness to its magneto, apart from very occasional cleaning its points, it has never missed a spark in many thousands of miles, whets more it will always be carried in the tool box!.

The Early MG Register Magazine is published by:

Early MG Society

Back to the News content

Back to the News content

![[Copyright/Credits]](../pics/mini-copyright.gif)

![[Home]](../pics/mini-home.gif)

![[Information]](../pics/mini-info.gif)

![[Feedback]](../pics/mini-mail.gif)