MGC Newsletter

Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

This describes the investigation and rectification of the distributor advance curve for the Lucas 25D6 distributor (41201 on the body plate) as fitted to the U.K. market cars for the 1968 model year, for a car in standard road-going configuration. The same principles will apply to the 45D6 for 1969, or for other markets, although data may differ. Modified cars of course require setting up on a rolling road to allow for the different breathing characteristics.

The workshop manual data is summarised in columns 1-3 of Fig. 1 From this it is obvious that the strobe setting of 20 deg. BTDC at 1000rpm (including 8 deg. BTDC static) is based upon mid range performance of the advance springs, with an acceptable variability being plus or minus three degrees below 1000rpm and plus or minus two degrees above the speed. The vernier knob is provided to make the necessary correction to achieve 20 at 1000rpm.

Removal of components to expose the weights shows that one is marked “14 degrees”. This is the maximum distributor centrifugal advance, which you can check with a protractor against the rotor arm, and equals twice this - 28 degrees - on the crankshaft. Look in column 1, to see that this is the maximum designed advance (centrifugal) at the red line, which equals 36 degrees with the static 8 degrees included. These are all, of course, vacuum disconnected numbers.

Two springs are provided to control the outward motion of the centrifugal advance weights and thereby regulate the advance with engine speed. The first small/primary/spring hangs loose on its mounting pegs until a certain advance has been reached, whereupon it is placed in tension and contributes its high rating to that of the first spring, to provide a flatter second part of the total advance curve.

One feature is missing from the workshop manual, and that is an advance value at some speed between 2600 and 5300rpm. We need to know if we are obtaining too much advance too soon, and I have scaled a value at 4000 rpm assuming a linear combined spring rate since we must be working within the springs’ load-to-extension limits of proportionality.

The engine was set at 8 deg. BTDC static advance, and curve measured on the original springs, now at 100,000 miles. The results in cols. 4 and 5 show that the first spring is now much too weak, and that the second is either weakened, or its end hooks are stretched, or its mounting pegs have worn to give too great a clearance when the spring is slack. Maximum advance is being obtained at only 4000 rpm.

There was also a lot of timing variability at low engine speeds. The car has been run with an overall “correction” of minus 4 degrees of retardation, but this is a bodge and the curve is the wrong shape.

The search for spare parts followed a fruitless and no doubt by now well-worn-trail - Lucas, Unipart, Bromsgrove, C-Register. Restorers and overhaul outlets were very willing to sell a recon unit for between £60 - £100 but not to part with springs, even if they had them, which three outlets frankly admitted they had not. Checks on my distributor for vacuum function, top bearing, and cam wear showed it to be quite serviceable, apart from the springs.

I was reminded that Moss supply a set of tuning springs under part number TT1903. There were found in the Triumph Tune catalogue, long forgotten since TR6 days, and were also in the Moss M.G. Performance Manual under the same part number, page E20 for the 1500 Midget. A set of 5 was purchased for £8.20 including p/p & VAT.

They were measured, together with those removed from the MGC with results as shown in fig 2 the end hooks on the Moss springs show that the first four are meant to replace the first spring of a pair and what I have called No.5 is a replacement for the second spring. Spring rate (extension per unit load, or indirectly, degrees of advance per intervals of rpm increase) is determined by wire diameter and number of turns. The length is also important in determining the amount of pre-load applied, which will change the revs at which a certain amount of advance will be obtained, without changing the overall proportionality, i.e. the spring rate will remain the same.

Moss 1 was fitted in place of the small MGC spring, with results in cols. 6 & 7. Advance below 1000rpm has been slightly reduced, but the second spring is obviously a point for attention. Moss 2 as supplied was a loose fit on the first spring pins. Shortening 1/32” to 20/32” just nipped the pins (pegs), and reducing to 19/32” gave a fit with a little initial tension. The results in Cols. 8 & 9 show that 6 turns of 27 thou wire gives a too high rated spring. It was decided to return to Moss 1 and shorten it to 18/32”. From Cols. 10 & 11 it will be seen that this had the desired effect of producing mid-spec. Advance up to 1000rpm, but there whereas the advance at 1200rpm has been reduced from our original 26 degrees to 24, we really need to have 22 for mid-spec result. Obviously the second spring must be brought into action by the time that 1200rpm is reached. It can be seen (co.1) that the average crankshaft configuration centrifugal advance spec at 1200rpm is 14 degrees, equals 7 on the distributor. Remembering that the total movement available corresponds to 14 degrees, than the second spring should come into tension at roughly halfway in the total movement. This is quite easy to judge either by eye, or measure with a protractor, or with internal callipers against some fixed reference point. To achieve this, the second MGC spring was shortened by 1/32”, by re-setting one end.

The test in Cols. 12 & 13 show that the desired result has been achieved, and that the actual advance curve is quite a good match to the mid-spec values. The maximum 36 degrees can safely be assumed at 5300rpm, and it cannot be exceeded due to the stop on the movement of the weights (besides which, testing at these revs in the Close will probably visits from the Noise Gestapo - the curtains twitch at 2600rpm!)

As this work was being completed, Dave Romer replied from New Zealand to a letter I had written about his article in MGCC Auckland’s MaG (Spet 1993) when he tackled much the same problem, and, it seems, came up with very much the same answer - a stronger primary spring and shortened the secondary, to meet a problem on their 96 octane leaded - they are now, of course, a totally lead-free country (96 octane). He has kindly sent me a pair of his new springs, and these I have measured and shown in the last two lines of Fig. 2 Dave writes - “I think you will find the enclosed pair of springs will be quite satisfactory although you may need to advance the dissy a little (3-4 degs.) the secondary springs is the same strength as the original although a few thou shorter - you can adjust the length by bending the hooks in or out. The primary spring is quite a bit stronger and also shorter and gives an advanced of 15-16 degrees at 2000rpm whereas the original goes to about 20 degrees when the secondary spring starts to act.” Dave has 14 sets of these springs available at NZ$10 per set to cover costs.

Gerald Sweatman\GCD1 1917G

| RPM | CRANKSHAFT CENTRIFUGAL ADVANCE |

+8 STATIC |

STROBE MID-SPEC |

ACTUAL | DIFF. FROM MEAN |

ACTUAL | DIFF. FROM MEAN |

ACTUAL | DIFF. FROM MEAN |

ACTUAL | DIFF. FROM MEAN |

ACTUAL | DIFF. FROM MEAN |

| 700 | 0-6 | 8-14 | 11 | 16 | +5 | 14 | +3 | 11 | 0 | 10½ | -½ | 10½ | -½ |

| 900 | 6-12 | 14-20 | 17 | 23 | +6 | 22 | +5 | 12 | -5 | 18 | +1 | 18 | +1 |

| 1000 | 20 | 20 | 25 | +5 | 25 | +5 | 14 | -6 | 20 | 0 | 20 | 0 | |

| 1200 | 12-16 | 20-24 | 22 | 26 | +4 | 26 | +4 | 16 | -6 | 24 | +2 | 22 | 0 |

| 2600 | 16-20 | 24-28 | 26 | 29 | +3 | 29 | +3 | 30 | +4 | 26 | 0 | ||

| 4000 | 20-24 | 28-32 | 30 | 36 | +6 | 36 | +6 | 37 | +7 | 32 | +2 | ||

| 5300 | 24-28 | 32-36 | 34 | ||||||||||

| Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| FROM WORKSHOP MANUAL FIGURES AT 4000rpm ARE ESTIMATED |

ORIGINAL SPRINGS FIRST AT 17/32 SECOND AT 22.5/32 |

FIRST: MOSS 1 AT 19.5/32 SECOND: MGC ORIGINAL AT 22.5/32 |

FIRST: MOSS 2 AT 19/32 SECOND: MGC ORIGINAL AT 22.5/32 |

FIRST: MOSS 1 AT 18/32 SECOND: MGC ORIGINAL AT 22.5/32 |

FIRST: MOSS 1 AT 18/32 SECOND: MGC ORIGINAL AT 21.5/32 |

||||||||

| L | D | W | I | N | ||

| TT1903 No.1 | 19.5/32 | 6/32 | 0.020 | 6/32 | 6 | Used at 18/32" |

| TT1903 No.2 | 21/32 | 6/32 | 0.027 | 8/32 | 6 | |

| TT1903 No.3 | 20/32 | 9/32 | 0.035 | 8/32 | ||

| TT1903 No.4 | 21/32 | 9/32 | 0.038 | 9/32 | 5 | |

| TT1903 No.5 | 23/32 | 9/32 | 0.038 | 9/32 | 5 | |

| MGC SMALL | 17/32 | 8/32 | 0.018 | 6/32 | 5 | |

| MGC LARGE | 22.5/32 | 7/32 | 0.044 | 9/32 | 5 | Used at 21.5/32" |

| D. ROMER SMALL | 15.5/32 | 6/32 | 0.018 | 6/32 | 8 | |

| D. ROMER LARGE | 22/32 | 7/32 | 0.046 | 10/32 | 5 | |

| All dimensions in inches Units of 1/32" or 0.001" L=Overall length inside hooks D=Outside diameter of coil W=Wire diameter L=Length of coiled part N=Number of turns |

||||||

Finally, here is Dave’s article. So after all, there are two sources for suitable distributor repair springs which have been N/A for the last twenty years.

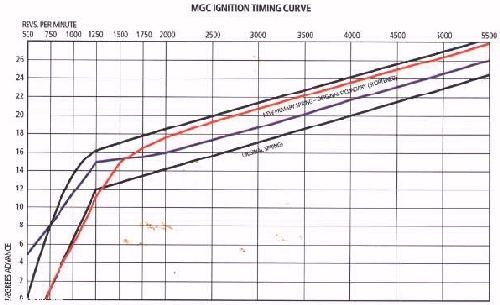

JY 7979 has standard combustion chambers and exhaust ports; inlet ports smoothed and the edges of the inlet manifold rounded off; a tubular free flow exhaust manifold inplace of the restrictive cast iron pieces. These modifications improve the performance, but not enough to get really excited while there was something that was not right. This car suffered from pre-ignition (pinking) at anything under 1800 rpm with more than about a third throttle so I carefully made a graph of the ignition timing (see graph) and from that it was obvious the primary advance weight spring (little weal spring) was flogged out over the years of use. Replacing this spring with a slightly stonger one than the original standard primary spring and shortening the secondary spring by .025” produced the correct results for 96 RON petrol we run our cars on (see graph). This new primary spring and slightly stronger secondary spring meant that the advance was 0 engine was idling.

I had new primary and secondary springs made, but as the price was nearly the same for 3 or 20. I opted for 20. If any owner wants new dissy advance springs for their car, I can supply at $7.50 a pair (cost to me) for a smoother and more responsive perfromance without any tendency to pinking on NZ 96 octane leaded petrol only, fit these advance springs.

MGC (Auckland) Representative. David Romer.

Vertical axis - degrees advance, Horizontal axis - revs per minute

Vertical axis - degrees advance, Horizontal axis - revs per minute

MGCC Home Page

More on the MGC Register

Back to the News content

Back to the News content

![[Copyright/Credits]](../pics/mini-copyright.gif)

![[Home]](../pics/mini-home.gif)

![[Information]](../pics/mini-info.gif)

![[Feedback]](../pics/mini-mail.gif)