Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

Click here to add your MG News.

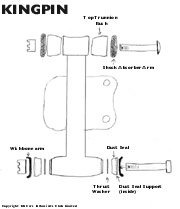

In these days of struts, & multi-link suspension systems, the bad old kingpin may need some explanation. All four wheels of a car run on hub bearings which allow them to rotate, but it is the kingpin which allows the front wheels to turn with the steering wheel. On the MGB & earlier MGs it consists of a metal pin which joins the the bottom wishbone/spring pan with the lever arm shockabsorber at the top. It fits through two soft metal tube shaped bearings in the back of the hub (or stub axle) so that the hub is free to turn controlled by the steering assembly. At the bottom, where it joins the wishbone, there is another tube shaped soft metal bearing (the bottom trunnion) which allows the wheel to stay more or less vertical as it moves up & down in relation to the car.

It is these soft metal bearings which wear, causing the dreaded play which regularly fails the mot test. Modern bearings have made life for the old kingpin more difficult for two reasons. Firstly, they last often for well over 100,000 miles and require no maintainance, so consequently kingpins often get the 'no maintenance' treatment as well. Secondly, they usually through design have no play in them until they start to fail, when they must be replaced, so mot testers have become far less tolerant of any play in this area. In the old days a small amount of kingpin play would probably have been expected & tolerated.

Kingpins by design need regular maintenance in the form of greasing, ideally every 1500 miles. This design comes from a time when mileages were lower (no motorways) and daily maintenance was part of the motorists routine, indeed to read some early servicing schedules many of us would probably be stopping several times on the way to work to carry out some routine maintainance or other ! Grease is applied via the three grease nipples on each kingpin assembly. A grease gun is required to force the grease into the bearing, and ideally this should be pumped in until it starts to ouse out from between the kingpin & the stubaxle. If the grease will not go in, the nipples can be unscrewed & freed up or replaced individually. It can also be a good idea to 'flush' the bearing through first to expel any water by pumping in thick oil first, followed by the grease.

Kingpins by design need regular maintenance in the form of greasing, ideally every 1500 miles. This design comes from a time when mileages were lower (no motorways) and daily maintenance was part of the motorists routine, indeed to read some early servicing schedules many of us would probably be stopping several times on the way to work to carry out some routine maintainance or other ! Grease is applied via the three grease nipples on each kingpin assembly. A grease gun is required to force the grease into the bearing, and ideally this should be pumped in until it starts to ouse out from between the kingpin & the stubaxle. If the grease will not go in, the nipples can be unscrewed & freed up or replaced individually. It can also be a good idea to 'flush' the bearing through first to expel any water by pumping in thick oil first, followed by the grease.

To check a kingpin for play, jack up the front of your MG so that the wheel is off the ground just enough to slide a tyre lever under the tyre and lever the wheel up & down. Have a close look at the kingpin bearings and check for any play up & down. Then jack up the car a bit further & holding the top & bottom of the tyre try & waggle the wheel vertically. Then do the same horizontally. If play is only felt vertically then this implies kingpin wear. If there is play in both directions then there may be play in the wheel bearing. Look closely for the play behind the wheel to check if the wheel is moving on the hub (wheelbearing play) or if the hub is moving on the kingpin (kingpin play).

If any play found is only slight, this may be overcome by greasing the kingpin to take up the play. Recheck after greasing and if any play is still detectable then the kingpin will need replacing. If you only have wheelbearing play then this may be adjusted by reducing the thickness of shims between the two bearings in the hub so that the wheel will still spin freely when the hub nut is done up, but with no play. If wheel bearing play is excessive or the bearings are noisy when the wheel is spun, then they may also need replacing ( they will still need to be adjusted with shims).

If seizure of the kingpin is suspected because of heavy steering, you can check which kingpin is to blame by disconnecting the steering arms. The wheel will then be free to turn with no resistance from the steering rack. You may need a press tool to force the tapered pin of the trackrod end out of the steering arm.

If you are going to attempt to replace a kingpin at home, you will need to get an exchange kingpin/stubaxle assembly ready built up. This is because the bearings in the stubaxle need to be reamed out with a special tool after press-fitting, and the top swivel joint shimmed when the top nut is done up to control tightness & up & down play. All of this is best done by a specialist, and mass produced reconditioned assemblies are often of variable quality, so check them before fitting. Your old assembly will be needed by the specialist in exchange, otherwise expect a hefty surcharge or in some cases refusal to supply.

2. Remove brake pad retaining pins & pads. Knock back the calliper bolt locktabs, undo the two calliper bolts & remove calliper, supporting it out of the way so as not to stretch the flexible brake hose.

3. Remove the hub nut & slide the hub/disc assembly off the stub axle, taking care not to drop the beaings out of the hub. Unbolt the brake dust shield from the stubaxle. Disconnect the steering arm from the trackrod end.

4. Support the lower wishbone/spring pan on a trolley jack. Undo the top trunnion bolt, slide it out and carefully lower the spring pan on the trolley jack to release the compression in the spring. The lower trunnion bolt can then be removed, noting the order of dust seal support, dust seal, thrust washer on each side of the kingpin between the wishbone arms. The bolts holding the wishbone arms to the spring pan can be loosened to facilitate removal & refitting of kingpin assembly between them.

(At this stage the wishbone arms can be removed completely if you wish to replace the inner wishbone bushes or upgrade them to V8 spec. These bushes are pressed into place using a vice. While the arms are removed check the pin they pivot on bolted to the crossmember for straightness.)

(At this stage the wishbone arms can be removed completely if you wish to replace the inner wishbone bushes or upgrade them to V8 spec. These bushes are pressed into place using a vice. While the arms are removed check the pin they pivot on bolted to the crossmember for straightness.)

5. Fitting up the new kingpin/stubaxle assembly is the reverse of the above. You will have to transfer the steering arm to the new stubaxle assembly before fitting. Upper & lower trunnion bolt kits are available which will give you all the new washers & spacers that you need. Use the trolley jack again under the spring pan to compress the spring so that you can get the top bolt through (you may need someone to sit on the wing & hold the car down for this!).

6. Refit the dust shield to the stub axle.

7. Refit the hub & hub nut, shimming the bearings if required. Remove shims to tighten bearing, add them to slacken. Shims are available in various thicknessess up to 10 thou. The bearings should spin freely with no play when correctly adjusted.

Note: there is a thick spacer washer which goes behind the hub on the stubaxle which often gets left in place when the hub is first removed so check this has been swapped to the new kingpin assembly.

8. Refit the calliper & pads. (If original pads are refitted, rough up the pad surface to help them re-bed in to the discs and check discs are clean).

8. Refit the calliper & pads. (If original pads are refitted, rough up the pad surface to help them re-bed in to the discs and check discs are clean).

9. Check the tightness of all bolts, and that split pins have been fitted to trunnion bolts, & wishbone arm pivot nuts if the arms have been removed. Check the calliper locktabs have been knocked back against the bolts.

10. Finally, don't forget to grease the new kingpin thoroughly, and make a note of the mileage ready for the next service.

|

Stuart L Payne LMG (Kent) Ltd 21 Upland Road Bexleyheath Kent DA7 4NR Tel: 0208 303 4811/2593 Web site |

|

![[Copyright/Credits]](http://www.mg-cars.org.uk/pics/mini-copyright.gif)

![[Home]](http://www.mg-cars.org.uk/pics/mini-home.gif)

![[Information]](http://www.mg-cars.org.uk/pics/mini-info.gif)

![[Feedback]](http://www.mg-cars.org.uk/pics/mini-mail.gif)