| THE M.G 'Midget is a car that has had a very long and successful life, and in one or other of its many forms it has been owned, loved and longed for by a large number of people interested in motoring. In the various forms in which it has appeared since its introduction its character and general conception have remained unchanged. However, many detail changes have been made through the years in the interests of performance, comfort and economy. During this process the car has, to a certain extent, grown up. For example, the power unit has a capacity of 1,250 c.c. compared with 847 cc. at the beginning, in 1929. The present model, known as the TD, also has independent front suspension and two leading shoe brakes, to name only two chassis features. Although the body is now larger it still | retains the family

likeness of its ancestors, and the car not easily mistaken for any other

marque. In view of its popularity, and, the type of owner for which it is designed, there is no'doubt that where several M.G. owners are gathered together the subject of the performance of their respective cars will be freely discussed. The question of tuning for increased performance is one on which much has been said, and is something that can lead to either success or disappointment. In either case it is likely to be costly in both time and money. With this in mind the M.G. company have very wisely carried out a considerable amount of development work to guide the owner in his quest for improved performance. Brief details of a number of different tuning stages have been listed in |

|

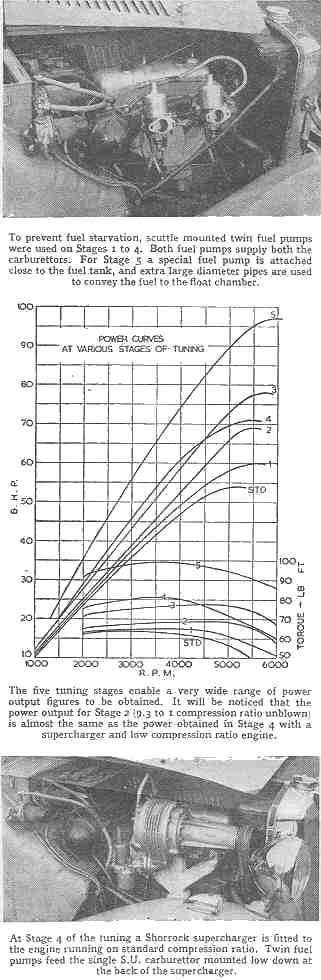

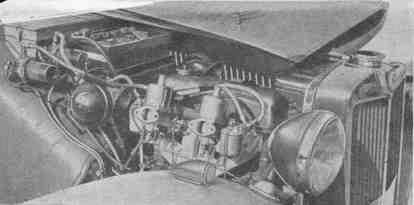

When tuned to Stage 5 the 1 1/2-litre engine in supercharged form develops 97 b.h.p., yet with the exception of valves and springs its components are standard. The Shorrock supercharger is belt driven from a pulley attached to the crankshaft in place of the starter dog, and it is supplied with oil from the main engine supply. External piping connects the oil filter mounted below the dipstick to the oil pump, which can be seen below the dynamo. |

|

a booklet issued by

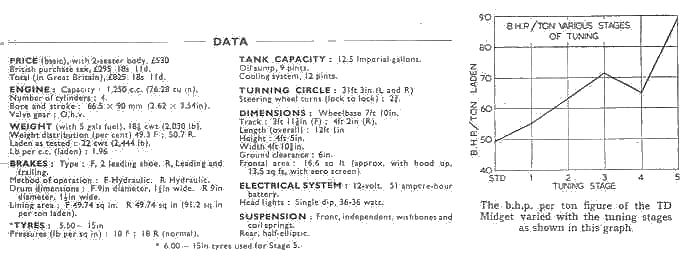

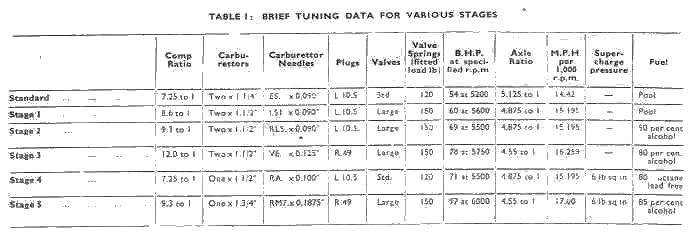

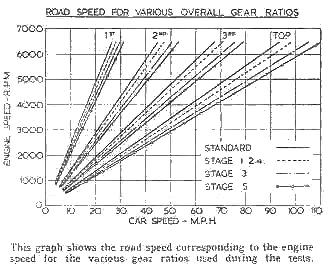

the manufacturers, called Tuning for M.G. Midget Engines. Now, it must be pointed out that although the manufacturers are in a-position to say what should be done, and also to supply the special components required for some of the stages, they are not able to supply new cars in a tuned form or to tune owners' cars, as this would, of course, interfere with normal production. However, if it is known what to do and what not to do there is a good chance of success. More important even than this, perhaps, is a clear idea of what the ultimate result is likely to be when the tuning is finished. Consequently, The Autocar has, over a period of several months, exhaustively road tested a TD M.G. in its various tuning stages from standard production to Stage 5. Before any tuning is attempted it must be decided for what purpose the car is required; also-and this will to a certain extent be inter-related with the first consideration- what type of fuel is available to run it on. The fuel question is of vital importance, and until this has been decided very little tuning of any kind can be done. Each type and blend of fuel has what is known as a highest useful compression ratio; therefore, unless the octane rating of the fuel will permit, there is no point in increasing the compression ratio, which is one of the best-known methods of increasing performance. Another method of increasing engine output is by supercharging, which may also in some cases be accompanied by an increase in compression ratio. Apart from the fundamental changes of the type mentioned, there are two other ways of improving engine performance. One is to reduce the friction between the moving parts, and the other is to improve the volumetric efficiency or breathing. These two items are not brought about by any form of magic, but by hard work and skillful use of tools, much patience, a basic knowledge of what can be done and cannot be done, and still more hard work. Making the Most of the Power A stage-by-stage treatment-of the engine will be given later, but before this is done there are other aspects of the tuning that must be considered. Briefly, the performance of a car depends on the power required relative to the power that is available. Now, assuming that the total weight is not affected much during the tuning, and also that the body shape remains unchanged, the curve showing the power required to drive the car will remain the same. To determine the required overall gear ratio it is necessary to have a knowledge of both the power required and the power available if the best overall performance is to be obtained. If the gear ratio has been determined for a car powered by an engine that develops, say, 54 b.h.p., as in the standard TD M.G., it is obvious that if the power out- put is increased to any marked degree some modification to the overall gear ratio will be required. If this is not done the engine will have exceeded its maximum safe working speed in r.p.m. before the maximum speed is reached corresponding to the power available. This means that for a given car, if the b.h.p. is increased I the m.p.h. per 1,000 r.p.m. of the engine on top gear must also be increased, and to do "this the gear ratio must be lowered [Thus providing a higher gear.-ED.] or a similar effect produced, for example, by fitting larger diameter tyres to the rear wheels. Modifications made to the axle ratio on the M.G. are listed in Table 1, and a graph shows the effect on the performance |

| in the indirect

ratios produced by these changes. The effect of weight is important in tuning,

but it should be remembered that it is the total drag that affects the maximum

speed, 'and the weight that affects acceleration. However, if the weight is not

kept to a minimum the resultant loss of potential acceleration may mean that

the car must slow down for a comer or because of other traffic, before its

maximum speed is ever reached; also, the lighter the car the less work there is

for the brakes. The car used for these tests was first submitted in standard trim. It was put through its paces, and, in fact, given the normal Road Test routine, including several hundred miles of normal road running to enable the driver to get to know the car as regards both performance and feel. In standard trim the Midget is a very satisfactory car. On looking back, after having driven it when its maximum speed was around the 100 mark, it would perhaps be thought slow by those interested only in sheer performance. Yet the ultimate maximum speed is not the only consideration, and in standard form the car recorded a mean maximum speed of 72.5 m.p.h., and this from an engine of only 1-41-litre capacity. On Pool fuel the engine is very smooth and flexible, so that the car is quite suitable for use when frequent stops and slowing down are demanded, as well as for fast open-road cruising. Stage One Perhaps the most noticeable increase in performance, yet one that keeps the car still very much an everyday vehicle as opposed to one that is used for special purposes, is the initial tuning modifications from standard to Stage 1. This is a simple tune-up and consists of raising the compression ratio to 8.6 by I (by means of machining -3/32 in off the cylinder head face), polishing out the ports, fitting larger valves and |

consequently stronger

valve springs, and replacing the 1.25in diameter twin S.U. carburetors with

1.5in diameter components, fed by the twin fuel pumps. Modifications to the

chassis consisted of lowering the axle ratio from 5.125 to 4.875, to I and

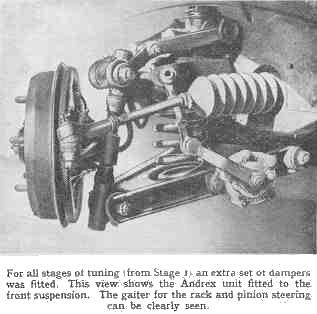

fitting an extra set of dampers. Also, purely for the personal comfort of the

driver, who was not in favour of driving with the windscreen flat with air

temperatures around freezing point, a glass plate type of defroster unit was

fitted to the windscreen. The first impression on driving the car in Stage I form was the very considerable increase in liveliness that it has, and under test conditions this impression was confirmed. The maximum speed was increased by 5 m.p.h. and there was also a marked improvement in the acceleration figures through the gears. Acceleration times in one gear from constant speeds, however, were, generally speaking, longer. Now this fact is interesting as it shows one of the fundamental things about tuning that is sometimes overlooked; that is, as the top end performance is increased, the bottom end power and consequently some of the flexibility also are often lost. For example, if the valve throat diameter is increased to improve the breathing at the top end the gas speed at low engine speeds will he reduced. This means that the pulling power and flexibility at low speeds on top gear will perhaps not be very good, and in consequence more use of the indirect gears must be made. In turn this may result in an increased fuel consumption. This trend can be seen throughout the whole of the tests, and confirms a phrase in the tuning book, " Power costs Money." Now although there is a very definite gain, in performance this is not obtained without some loss in smoothness. However, it must be remembered that at this stage the car is still running on Pool fuel. During the tests some pinking was noticed, but this can be reduced to a minimum by using the indirect gears and not letting the engine slog away at low |

speed on top gear.

The car is quite happy in city traffic generally, yet it should be recorded

that on one occasion only, in very dense slow-moving traffic, it did show signs

of getting hot. On all other occasions, including fast main road and hilly

journeys, as well as during the actual performance testing, no trouble of this

kind was experienced. With the extra set of spring dampers fitted the car has a

much firmer ride at high speeds at the cost of some increased vibration over

rough surfaces at low speed. For Stage 2 the compression ratio is further

increased to 9.3 to I by machining a total of 0.125 in off the cylinder head,

which is the absolute maximum that can safely be removed. As in Stage 1, large

valves are used, and the twin 112-in bore S.U. carburettors were tuned to suit,

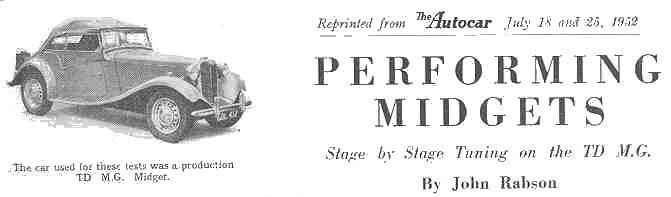

the 50 per cent alcohol fuel. At this stage the engine develops 69 bh.p. at

5,500 r.p.m. as compared with 54 b.h.p. at 5,200 r.p.m. when in standard form,

or 60 bh.p. at 5,600 r.p.m. with the Stage I tuning. Compared with Stage 1,

perhaps the most notice- able thing about the behaviour is the very

considerable in- crease in smoothness, yet the gain in maximum speed is not

nearly as marked for the 9 b.h.p. increase as it is between the standard engine

and -Stage I for an increase of only 6 b.h.p. This is, of course, brought about

by the shape of the power required curve, and shows the effect of wind resistance as the speed is increased. The acceleration figures from a standing start through the gears show an overall improvement; accelerations on one gear from constant speeds are slightly worse. The fuel consumption is considerably increased, but this is not surprising, because of its high alcohol content. It is possible to run in this stage of tune on 80 octane fuel. This would enable the car to be used for normal running in countries where this type of fuel is available. Both Stages 3 and 5 of the tuning are in- tended for competition use only, and will therefore be dealt with together later. Adding a Blower Next, then, we come to Stage 4, which consists of super- charging the engine in standard form, but using the 4.875 to I axle ratio (as fitted in Stages I and 2). In this form the engine is blown at 6 lb per sq in by means of a Shorrock supercharger, which is belt driven from the engine crank- shaft, and for this stage it is fed by a single 1.5 in S.U. carburettor. For test purposes 80 octane lead-free aviation fuel was used, although it is possible to run on 70 octane fuel, at the expense of a slight reduction in output. In the past there has been perhaps a feeling that when a car is supercharged it, at once becomes messy, unreliable, and likely to blow up at the slightest provocation. This may have been true in the past, when some of the problems connected with supercharging were not fully understood, but it certainly does not apply to the Stage 4 M.G. The general improvement in , filling and distribution brought about by the blower results in an overall improve- |

ment in performance as regards both maximum speed and acceleration compared with Stage 2. On the other hand, the fact that it does not have such a good bottom end as the standard engine is reflected by the acceleration figures from a constant 10 and 20 m.p.h. on top gear. It must be remembered that the change in axle ratio will affect the result slightly. However, compared with the general improvement in performance this effect is of little moment, as a driver could overcome it by use of the gears, yet it does show what is perhaps the major difficulty in tuning; that is, to obtain an overall increase in power output with-, out losing the bottom end or engine flexibility. In this supercharged form the car is quite suitable for normal road use, but the fuel consumption is, of course, increased as compared with the unblown engine; also, as the oil supply for the supercharger is taken from the engine, the sump must be replenished more frequently than when the engine is unblown. The supercharger is quiet in operation. In fact, it is not until the engine is really starting to rev that the familiar whine is heard at all. No difficulty in starting from cold was experienced. The stages dealt with so far cover tuning suitable for a car that is used to some extent as a normal road vehicle, In the next issue the two remaining stages will be considered that are intended purely for competition work and not suit- able for normal use. General impressions and results will also be discussed.  |

| SOME of the general problems connected with tuning have been

considered, together with results obtained with those stages that are suitable

for normal road operation if the correct grade of fuel is available. To

complete the picture there remain two further stages which are really suitable

only for competition work, although during tests the car was driven on the road

in both these conditions for a considerable distance. At Stage 3 the car has the character and, perhaps, the temperament of a racer. This is not surprising, as the engine now has a compression ratio of 12 to I obtained by using a cylinder head of standard dimensions in conjunction with special pistons. Large diameter valves are, of course, fitted, and the 80 per cent alcohol fuel is metered by twin I 'I'M S.U. carburettors. At this stage starting from cold is best performed with the aid of a rope and a tender car, unless there happens to be a team of strong men available to push. However, once the engine is warm starting can easily be performed with the standard starter motor, and in such  |

circumstances, during

the test, the response was almost instantane'ous. With 78 b.h.p. at 5,750

r.p.m. now available, it is necessary to change the rear axle ratio to 4.55 to

I to make effective use of the new-found top end power without over-revving the

engine. These modifications produce an increase in maximum speed of 3 m.p.h.

compared with Stage 4. They also give a noticeable improvement in the

acceleration times from a standing start through the gears, in spite of the

change in axle ratio. On the other hand, acceleration times on any one gear do

not show any improvement; in' fact, they are, if anything, slightly worse. The car is very pleasant to drive at this stage provided that the lack of bottom end flexibility compared with that available with the engine in standard form is remembered, and the car driven accordingly. It is also very important to maintain the correct engine temperature, as the cool  |

|

For Stage 3 (l2 to 1 compression ratio) large twin S.U. carburettors are used. These are supplied with fuel by the twin electric fuel pumps mounted on the scuttle, piped so that both pumps supply both carburettors. This is necessary to prevent possible starvation of fuel, as the excessive temperature caused by a weak mixture could produce extreme overheating. |

| running qualities of

the alcohol fuel can, in certain circumstances, cause over-cooling, which may

result in lumpy running at low speeds, accompanied by some hesitation when the

throttle is opened. During this test, which was carried out at an air

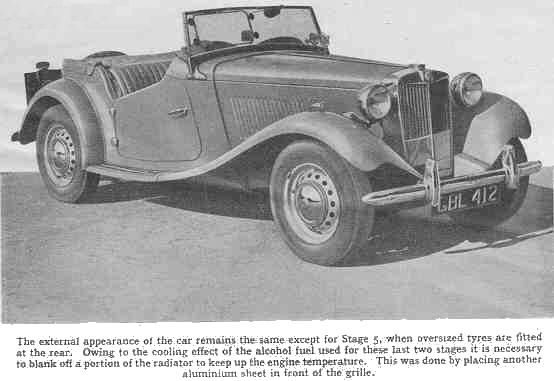

temperature of 59 deg F, it was found necessary further to blank off the

radiator for the acceleration tests in constant gears, although for other tests

the single aluminium sheet fitted, as shown in one of the photographs, was

entirely satisfactory. Mixture strength is of the utmost importance at this

stage, as any weakness could easily cause overheating, which could have very

serious results. Under normal conditions, this would not happen, but a

temporary starvation could take place if the car were driven with only a very

small quantity of fuel in the tank, and fuel movement during rapid cornering,

for example, permitted air to enter one of the fuel lines. It is therefore

advisable to keep a considerable quantity of fuel in the tank to eliminate this

possibility. The final test in this group is Stage 5, which consists of the 9.3 to 1 compression ratio engine, supercharged at 6lb per sq in by means of a Shorrock blower. As in Stage 3, the car is fitted with the 4.55 to I rear axle ratio, but oversized tyres are used to give 17 m.p.h. per 1,000 r.p.m engine speed, compared with 16.258 m.p.h. per 1,000 r.p.m for Stage 3 with 5.50-15 in tyres.. With 97 b.h.p. available under the bonnet, the little T.D. really does go like a bomb, |

and when driven on

the road it has been responsible for a number -of puzzled expressions on the

faces of drivers in cars that it has passed, and who did not know that the car

was tuned. Considering the type of body, which does not cheat the wind as well

as some, the maximum speed of 96 m.p.h. (approximately I m.p.h. per b.h.p.),

with the hood and side screens in position, is very good. It can be further

increased,' to just over the 100 mark if the car is &ted with a full

tonneau cover and an aero screen. What it would do with a full streamline body

must be left to the imagination, or to Goldie Gardner. Normal racing car drill

must be performed as regards plug changing at Stage 5. Often the engine could

be started from cold by the normal starter motor, although this was difficult

at times and the rowing method had to be used. Starting from hot could easily

be performed at all times with the starter. Because of its potential maximum

speed this Stage 5 test was carried out in Belgium on the Jabbeke motor road.

On the road itself, which is excellently surfaced, the car ran 'very well

indeed. However, on some of the smaller roads leading off the main highway the

pave is very uneven, and on these surfaces some irregularity in running was

noticed, but this stopped again as soon as the car returned -to a smooth road. This is interesting, and may have been caused by frothing of the alcohol, the condition being accentuated by the firmness of the suspension when fitted with the additional dampers. Under normal conditions the standard clutch was quite satisfactory in dealing with the much increased power output, yet under the strenuous conditions of the repeated standing start acceleration tests slip was experienced, but only at this stage. There are a number of points that arise from an examina- |

| |

An exploded view showing the mechanism of the eccentric vane type supercharger fitted to the M.G. engine. The inlet elbow is arranged to suit the three- bolt flange on the large carburettor used for Stage 5. In the centre of the inlet manifold at the bottom is the super- charger blow-off valve. Lubrication is provided by oil piped from the engine to the union that can be seen behind the rear end-plate of the supercharger. |

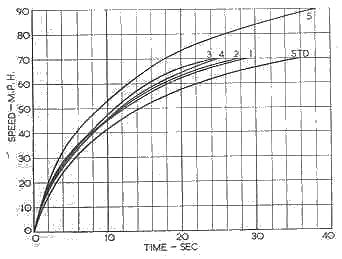

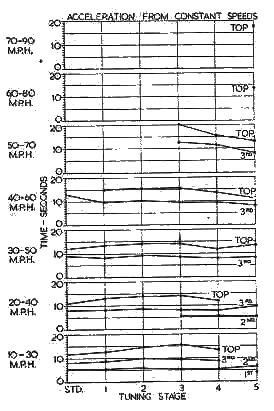

| tion of the results of these tests. First, before any tuning is undertaken at all it must be decided for what purpose the car is required. There is absolutely no point in tuning for its own sake with no ultimate aim in view; also an engine should not be tuned more than is necessary to give the desired result, as this would only unduly stress the components and also increase the fuel bill. Perhaps one of the things that is most noticeable is the way that engine flexibility at the bottom end is lost as the top end power output is increased. This loss, of course, can be compensated for by modifications in driving methods, which will result in an overall gain in performance, but again this will mean in- creased fuel consumption. This is perhaps best illustrated by reference to the graphs showing acceleration times on any one gear, and from rest through the gears. It will be seen that as the tuning proceeds it is possible to make the car go progressively more quickly if the gears are ,used. On the other hand, if the gears are not used the acceleration time from, say, 10 to 30 m.p.h. on top gear will get longer as the tuning proceeds, until at stage 5, for ex- ample, the car tested would not run satisfactorily below a speed of 25 m.p.h. on top gear, with the result that no figures on this gear at a speed below 30 m.p.h. were recorded. However, this was the only stage at which acceleration times for speeds of 70-90 m.p.h. on top gear could be recorded. This again emphasizes the fact that as the power available at the top end is increased by tuning, flexibility at low speeds is reduced. In other words, you cannot have it both ways. of this power being used in overcoming, wind resistance. becomes more and more noticeable. This is illustrated in the graphs showing the m.p.h. per, b.h.p.- engine output.. From these it can be seen that for the standard engine 54 b.h.p. gives a mean maximum speed of 72.5 m.p.h. An increase of 17 b.h.p. (to Stage 4) increases the mean maximum speed by only 9.5 m.p.h. | Again, at Stage 5 the engine develops 97 b.h.p., which represents an increase of 43 over the standard engine; this 43 b.h.p. results in an increase in maximum road speed of 23.5 m.p.h. at the top end, most of this power being used in overcoming wind resistance. That is why for a given body style the increase from the standard to Stage 1, which results in a gain of 5 m.p.h. for 5 b.h.p., is not repeated in the same ratio farther up the range. Stages 2 and 4 give rather similar results, and show two ways of obtaining somewhat similar outputs. Both the high compression ratio engine in Stage 2, and the supercharged standard compression ratio engine of Stage 4, can be driven on the road for normal transport with somewhat similar performance. What, then, should decide which arrangement of tuning should be used? For road operation the differences in output are not sufficiently great to be noticed under normal conditions. In fact, acceleration times through the gears from 0-50 m.p.h. are almost identical. However, above that speed the supercharged engine is at a slight advantage, though it is rather more thirsty than the unblown ver- |

sion. This is interesting, because Stage 2 is using a 50 per cent alcohol fuel, whereas the supercharged version (Stage 4) runs on 80 octane lead-free aviation spirit. For competition purposes handicap arrangements would obviously tend to militate against the use of a supercharged engine in any other form than Stage 5, as both Stages 2 and 3 could produce results similar to or better than those from the supercharged version at Stage 4, without penalization  The left-hand piston is of the standard

production type used for Stages, 1, 2, 4 and 5, while on the right is the

special piston used for Stage 3, which, in conjunction with a standard cylinder

head, gives the compression ratio of x2 to 1. The left-hand piston is of the standard

production type used for Stages, 1, 2, 4 and 5, while on the right is the

special piston used for Stage 3, which, in conjunction with a standard cylinder

head, gives the compression ratio of x2 to 1. from a competition angle. On the other hand, supercharging the engine according to Stage 4 does enable a very considerable increase in power output to be obtained with very little actual modification to the power unit, whereas the other stages require a number of internal modifications. It is therefore quite simple to convert the standard engine to Stage 4 and back to standard conditions again without obtaining a new or modified cylinder head, as would be required for most of the other stages. It must be remembered that modifications to the axle ratio are necessary to get the maximum output from the various stages of tuning. To enable all stages of tuning to be carried out it is necessary to have at least three cylinder heads and two alternative sets of pistons, as well as three sizes of carburettor and special valve gear, and with these components available the |

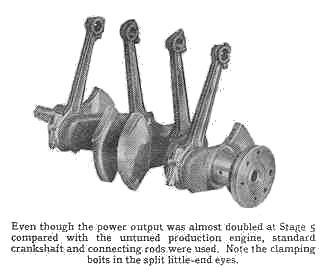

To obtain a compression ratio Of 9.3 to I (as used in Stage 5) the cylinder head is machined to form a compact combustion chamber. A standard piston is used. M.G. can be tuned to suit a very wide number of requirements. The general design and the construction of the power unit as a whole are sufficiently robust to enable these large increases in power output to be obtained without fear of component failure or general lack of reliability. Yet it must be realized that, as the tuning is increased and the components become more highly stressed, so will the rate of wear and tendency towards unreliability be increased. This is only natural and does not reflect in any way on the design; if fact, it speaks very well indeed of the engine design when it is realized just how much power can be extracted from it without modifying the basic components such as the crankshaft or connecting rods, for example. Obviously, any owner wishing to tune his car will have his own ideas as to how far he wishes to go, but, briefly,' from the tests it would seem that Stage I tuning would suit the requirements of most people who want their Midgets to go rather faster than average without too much of an increase in the fuel bill. Stages 3 and 5 shoulid be reserved for competition work only, while Stages 2 and 4 can be used for either road or competition work at the expense of an increased fuel consumption, and in a car used for road work, only provided that the correct type of fuel is readily available. |