UPHOLSTERY AND JACK

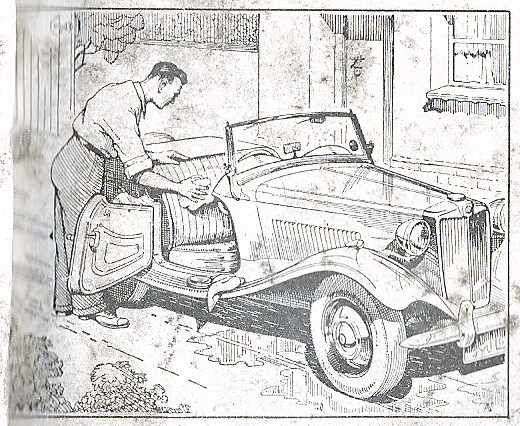

Care of Upholstery

Jack Operation

upholstery

The upholstery should be cleaned at regular intervals by wiping it

with a damp cloth and polishing it with a clean soft cloth when it is dry.

The use of polish is quite unnecessary.

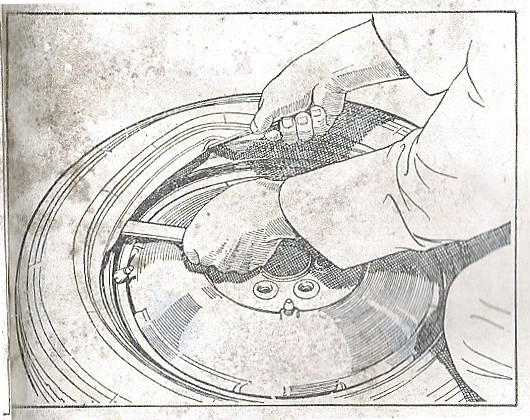

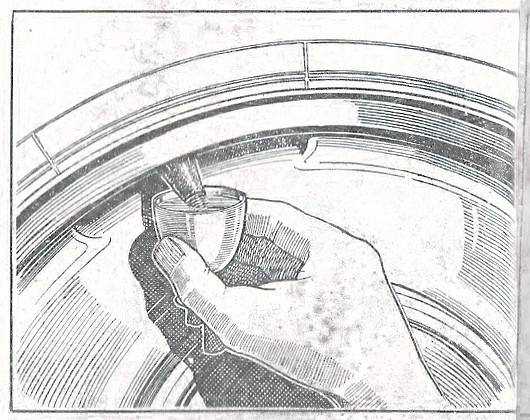

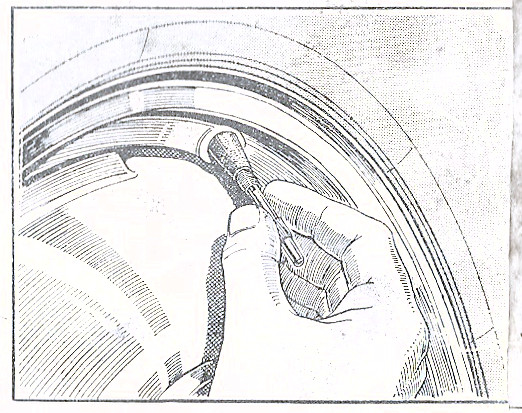

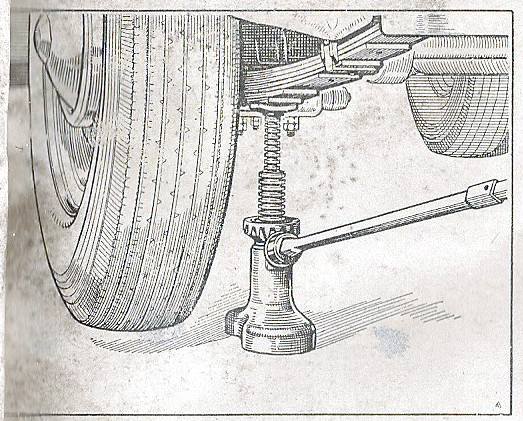

JACKING UP (REAR)

The screw-type jack should be placed under the rear spring, close to the axle, when lifting the rear of the car.

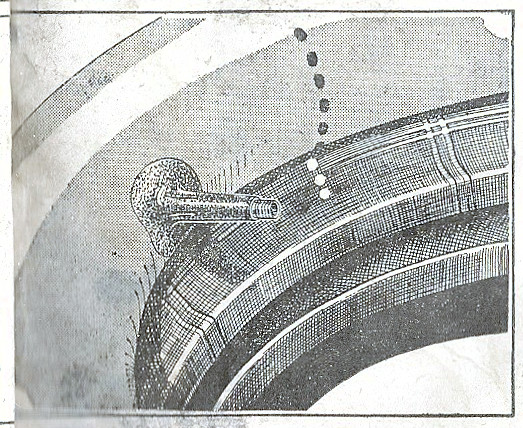

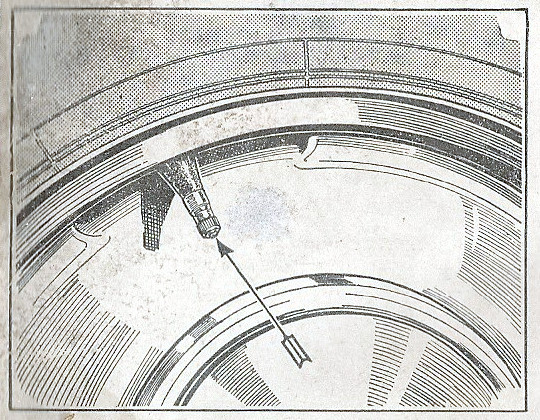

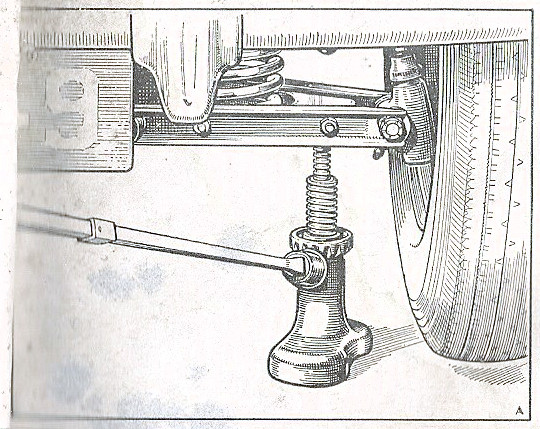

JACKING UP (FRONT)

The screw-type jack should be placed under the lower wishbones, with its pad engaging the depression between the spring seating and the lower link.

29