MAINTENANCE ATTENTION

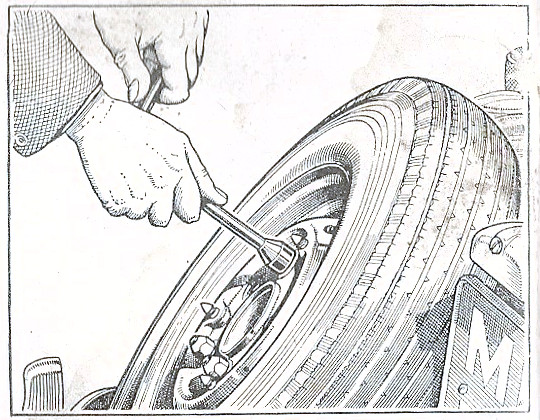

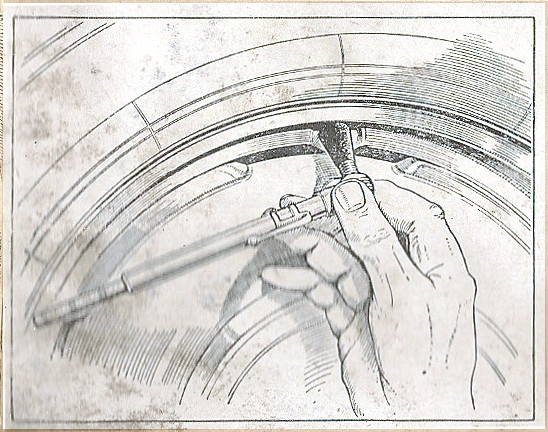

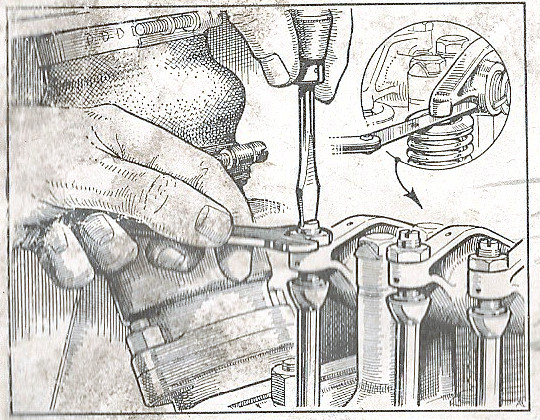

Valve Tappet Clearance

Clutch Pedal Clearance and Adjustment

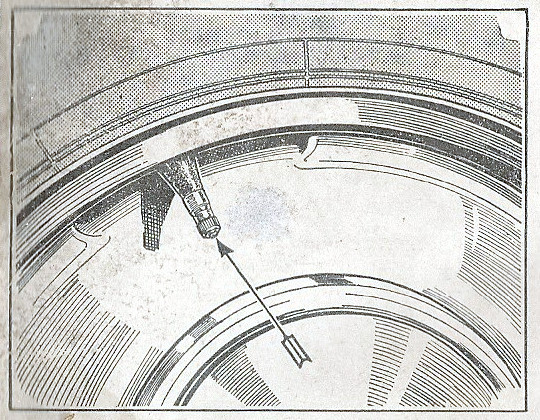

Valve and Tappet Clearance

Both inlet and exhaust valves should have a clearance of at least .019 in. (.49 mm.) when hot. It is of utmost importance to set

| No. 1 | valve | with | No. 8 | fully | open |

| No. 3 | “ | “ | No. 6 | “ | “ |

| No. 5 | “ | “ | No. 4 | “ | “ |

| No. 2 | “ | “ | No. 7 | “ | “ |

| No. 8 | “ | “ | No. 1 | “ | “ |

| No. 6 | “ | “ | No. 3 | “ | “ |

| No. 4 | “ | “ | No. 5 | “ | “ |

| No. 7 | “ | “ | No. 2 | “ | “ |

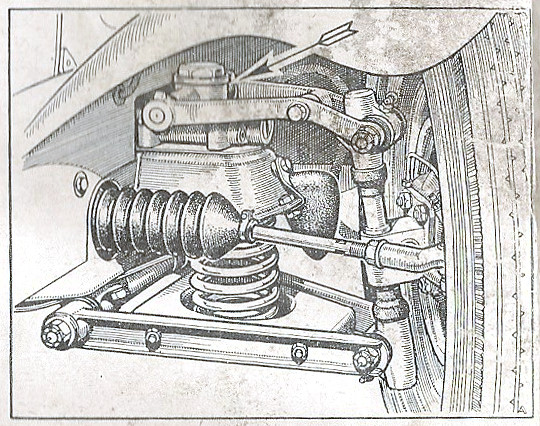

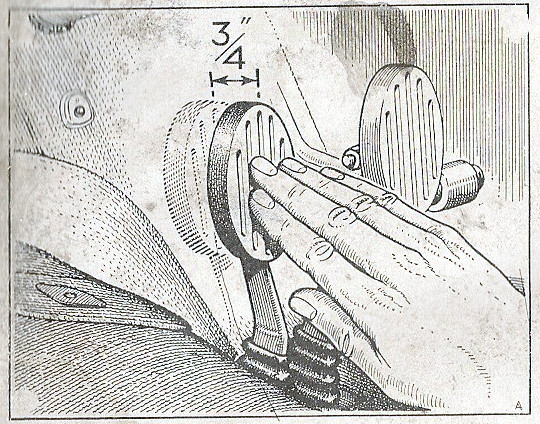

Clutch Pedal Clearance

It is of the utmost importance that the pedal has ¾ in. (22.0 mm.) minimum free travel before operating the clutch withdrawal mechanism. The free movement is easily determined by light hand pressure on the pedal.

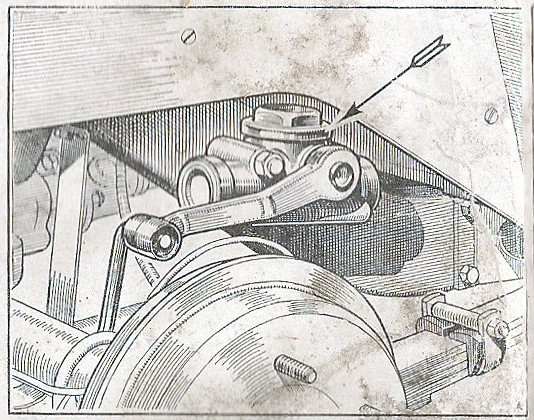

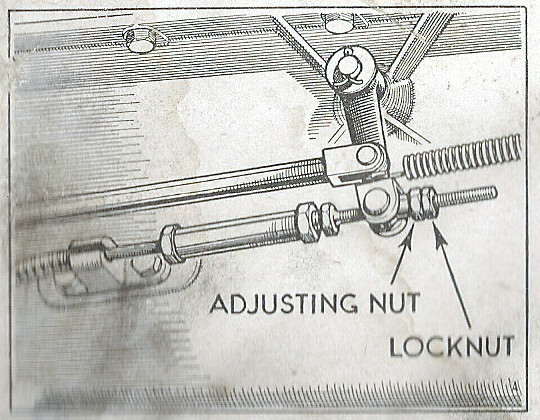

Clutch Pedal Adjustment

The stop limiting the travel of the pedal is then adjusted if required to give 3 in. (7.6 cm.) pedal movement after the ¾ in. (2.0 cm.) free travel, by means of the adjustment indicated below. The clutch pedal clearance (or free movement) is adjusted by means of the adjusting nut here shown, after releasing the locknut, until ¾ in. (2.0 cm.) free movement is obtained. Check the effective travel, making sure it is not less than 3 in. (7.6 cm.).

17