THE CARBURETTERS

Cleaning the Filters • Adjusting the Slow

Running • Adjusting Mixture Control Linkage

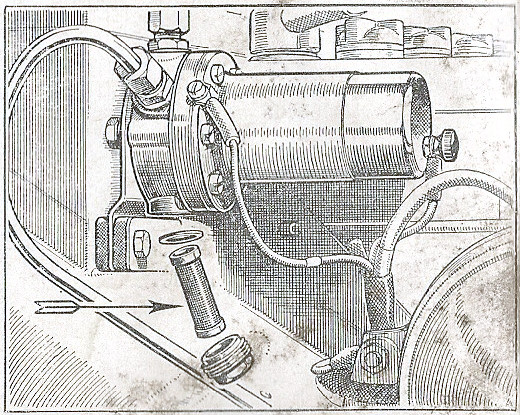

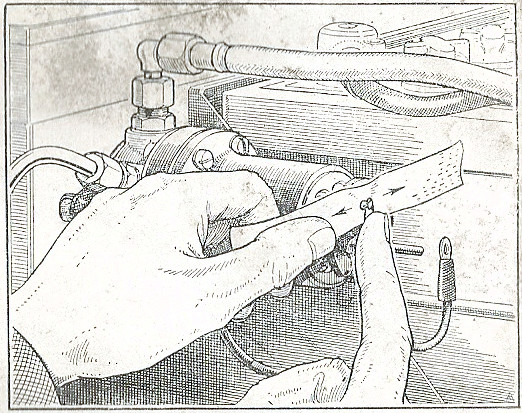

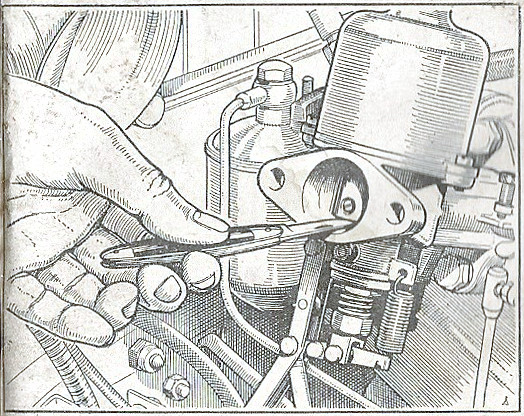

The Carburetter Filters

To ensure a free flow of petrol to the float-chambers the filters should be

removed at intervals of about 3,000 miles (5000 km.) and thoroughly cleaned with a stiff brush and

petrol. Never use rag. The filters are situated behind the banjo-type union at the junction of the

petrol pipe to each float-chamber lid.

Replace the filters with their helical springs first and

their open ends outwards. Replace the fibre washers correctly.

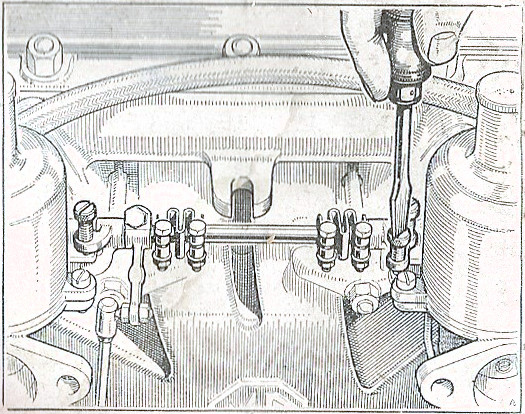

Slow Running Adjustment

Slow-running adjustments are carried out by adjusting the position of the carburetter

throttle lever stop screws, which are spring-loaded, until gentle slow running is attained.

It is

important that both carburetters are set exactly alike, and you are advised to entrust this to an M.G.

Dealer.

Make sure that there is a small clearance between the mixture and throttle inter-connecting

lever and its abutment screw.

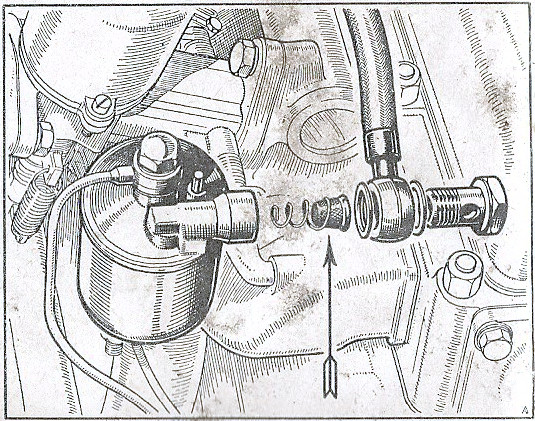

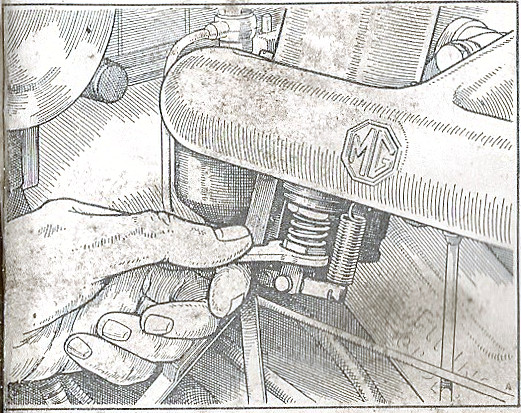

Mixture Control Linkage

Adjustment

When the mixture control knob on the instrument panel is right home there must be a

small gap between the adjusting screw and the operating lever on the front carburetter.

This gap regulates

the action of the throttle and the mixture control and should be set so that there is just clearance

between the end of the adjusting screw and the anvil of the rocking lever linked to the jet operating

lever.

50

THE CARBURETTERS

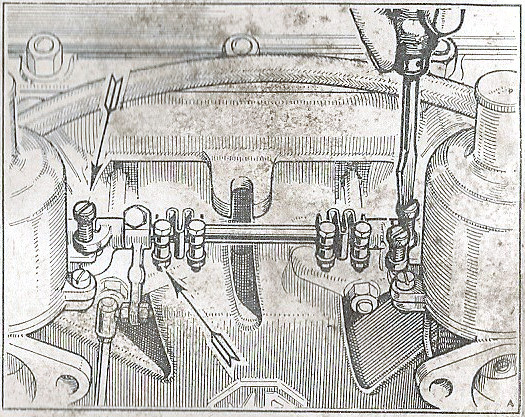

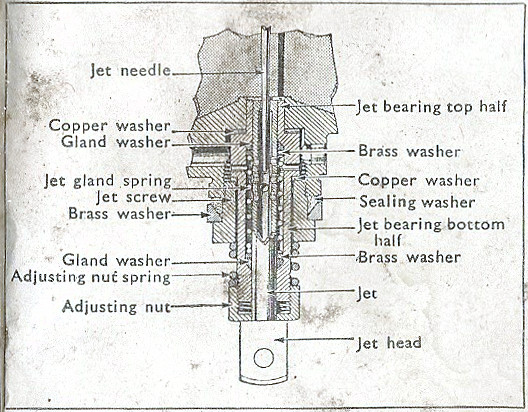

Adjusting the Jets

Adjusting the Jets

Run the engine until it attains its normal running temperature. Set the slow-running

screws on the carburetter throttle actuating levers so that the throttles are both open the same amount.

This is indicated by the same suction noise at each carburetter.

Disconnect the mixture control wire from the end of the brass lever actuating the

jets, and screw the jet adjusting nuts well downwards. Note that the jet actuating levers are held in

contact with the jet heads by their return springs and must be kept in contact the whole time.

The jet adjusting nuts should now be screwed inwards slowly (thus gradually weakening the mixture) until the engine idles evenly, firing on all cylinders regularly, and running at its best speed. This will be the normal slow-running position when the engine is hot and as the jet needles are the correct size the general performance on the road should be entirely satisfactory. Check by raising each carburetter piston 1/32 in. (.8 mm.). If the engine speed increases momentarily the setting is right. If the engine stalls the setting is too weak.

The mixture control wire may be reconnected when adjustment is satisfactory, care being taken to see that the control knob has ample clearance when the jet is in contact with the adjusting nut. Final adjustment for slow running is then carried out by adjusting each of the carburetter throttle lever stop screws an equal amount.

51