Periodical Attention

Use of the Oilcan

Draining the Cooling System

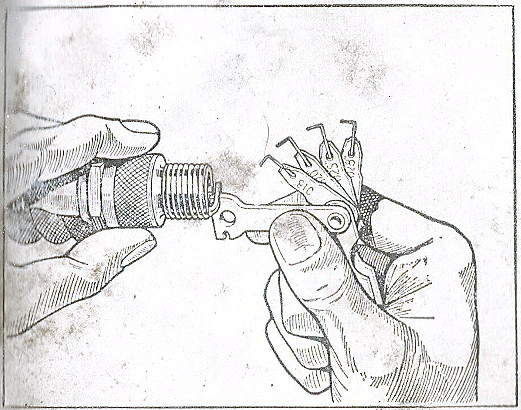

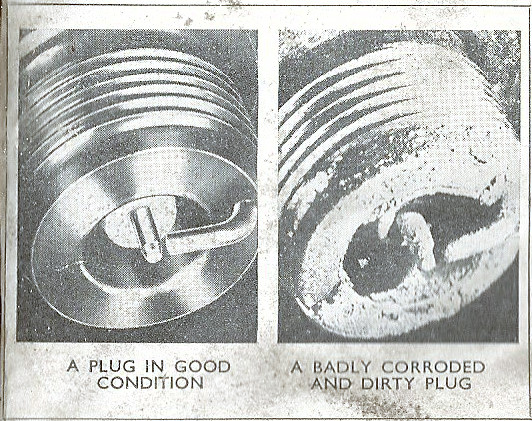

Examine the gaps of the sparking plugs and make sure that they are not too wide;

they should be .020 in. to .0221 in. (.45 mm. to .56 mm.). Apply grease gun filled with oil to

Ref. B

(age 36) to nipple on revolution indicator gearbox on dynamo.

Every 12,000 miles (20000 km.). Remove sump and clean oil filter. Check fluid

level in shock absorbers, refill if necessary with recommended fluid (see

page 18).

Use of Oilcan

The owner is advised to keep an oilcan filled with a light oil to Ref. F (page 36) to apply to the bonnet lock and prop mechanism and the door locks and hinges, etc., at frequent intervals. Attention to such details ensures trouble-free action and prevents undue wear. Make sure that all points receive attention.

draining the cooling

system

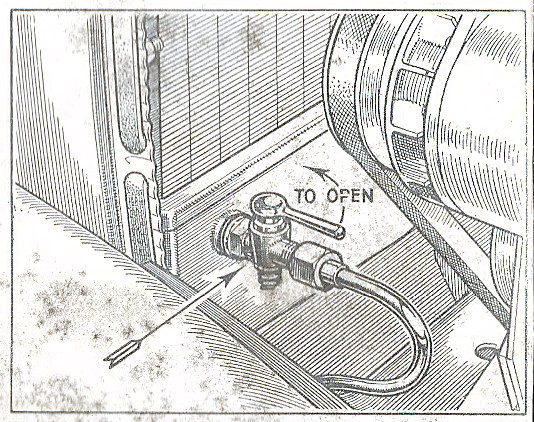

The radiator drain tap is fitted on the left-hand side of the radiator bottom tank, as indicated by the arrow in the top illustration.

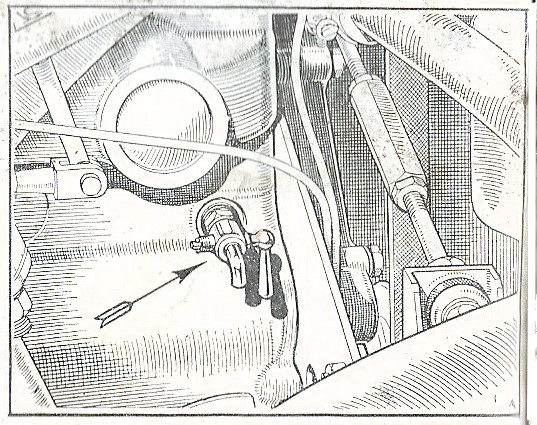

Owing to the location of the water pump a certain amount of water is trapped in the cylinder block and cannot be drained from the radiator.

A second drain tap is therefore fitted on the right-hand side of the engine at the lowest point of the cooling passages, as indicated by the arrow in the bottom illustration.

It is essential to open this tap to drain the system completely.

46

Cold Weather Precautions

Draining the Cooling System

Attention to Bodywork

Cold Weather Precautions

If the car is not stored in a warmed building, steps must be taken to prevent the cooling water

from freezing during frosty weather. Water upon freezing expands, with the result that there is a

very considerable risk of bursting either the radiator or the cylinder block by the pressure

generated. As a precautionary measure when frost is anticipated, the water should be drawn from the

radiator and engine (see page 46)

before the car is stored for the night, or, better still, an

anti-freezing solution may be used in the radiator.

We recommend owners to use Smiths "Bluecol" or Filtrate "Nevafreze"

non-erosive anti-freeze in order to protect the cooling system during frosty weather and reduce

corrosion to a minimum. The correct quantities of anti-freeze for different degrees of frost

resistance in the M.G. "TD" Midget are:—

| 7° F. ( -14° C.) | O° F. ( -18° C.) |

| 15% solution | 20% solution |

| Size 1A Size | Size 0+1Y |

| Quantity : 2 pints (1-14 litres) | Quantity : 2¾ pints (1-56 litres) |

If temperatures below 0° F. or —18° C. are likely to be encountered a solution of at least 25% of

Bluecol must be used.

Before introducing anti-freeze mixture to the radiator it is advisable to clean out the cooling

system thoroughly by swilling out the passages with a hose inserted in the filler cap, keeping the

two drain taps open. Only top up when the cooling system is at its normal running temperature, in

order to avoid losing anti-freeze due to expansion.

Make sure that the cooling system, is water-tight and examine all joints, replacing any

defective rubber hose with new.

Bodywork Attention

The car should be washed and dried thoroughly before applying polish. The use of a non-abrasive

polish is essential.

Apollo polish is recommended.

Grease and tar spots must be carefully removed with a wadding pad dipped in petrol. Chromium plating

should be washed with soap and warm water only. Metal polishes or abrasives of any sort must on no

account be used.

47