RECOMMENDED LUBRICANTS

| A | B | C | D | E | F | ||||

| Component | Engine and Air Cleaner | Gearbox, Steering Gearbox and Rear Axle (Hypoid Gears) | Wheel Hubs and Fan Bearings | Chassis Greasing, Nipples etc. | Cables and Control Joints | Oilcan and Carburetter | |||

| Climatic Conditions | Tropical and temperate down to 32° F. (0° C.) | Cold and extreme cold down to 0° F. (-18° C.) | Arctic below 0° F. (-18° C.) | Tropical and temperate down to 10° F. (-12° C.) | Extreme cold below 10° F. (-12° C.) | All conditions | All conditions | All conditions | All conditions |

| "ENERGOL" (Price's Lubricants Ltd.) | "Energol" Motor Oil S.A.E. 30 | "Energol" Motor Oil S.A.E. 20 | "Energol" Motor Oil S.A.E. 10 | "Energol" Transmission "E.P." S.A.E. 90 |

"Energol" Transmission "E.P." S.A.E. 80 | "Energrease" C.3 | "Energrease" C.1 | "Energrease" C.1 | "Energol" Motor Oil S.A.E. 20 |

| "SHELL" (Shell Mex & B.P. Ltd.) | "Shell" X—I00 S.A.E. 30 | "Shell" X—I00 S.A.E. 20 | "Shell" X—I00 S.A.E. 10 | "Shell" Spirax 90 E.P. | "Shell" Spirax 80 E.P. | "Shell" Retinax H for Hubs Retinax C for Fan |

"Shell" Retinax C | "Shell" Retinax C | "Shell" X—I00 S.A.E. 20 |

| "FILTRATE" (Edward Joy & Sons Ltd.) | Medium "Filtrate" | Zero "Filtrate" | Sub-Zero "Filtrate" | Hypoid "Filtrate" 90 | Hypoid "Filtrate" 80 | "Filtrate" R.B. Grease | H.P. Solidified "Filtrate" | "Filtrate" A.F. Grease | Zero "Filtrate" |

| "STERNOL" (Sternol Ltd.) | "Sternol" W.W. 30 | "Sternol" W.W. 20 | "Sternol" W.W. 10 | "Sternol" Ambroleum E.P. 90 | "Sternol" Ambroleum E.P. 80 | "Ambroline" R.B. Grease | "Ambroline" M.M. Grease | "Ambroline" A.F. Grease | "Sternol" W.W. 20 |

| "DUCKHAM'S" (Alexander Duckham & Co. Ltd.) | Duckham's N.O.L. "Thirty" | Duckham's N.O.L. "Twenty" | Duckham's N.O.L. "Ten" | Duckham's Hypoid 90 | Duckham'S Hypoid 80 | Duckham's H.B.B. Grease | Duckham's H.P.G. Grease | Duckham's "Keenol" K.G.I6 Grease | Duckham's N.O.L. "Twenty" |

| "CASTROL" (C. C. Wakefield & Co. Ltd.) | "Castrol" X.L. | "Castrolite" | "Castrol" Z | "Castrol" Hypoy | "Castrol" Hypoy 80 | "Castrolease" Heavy | "Castrolease" Medium | "Castrolease" Brake Cable Grease | "Castrolite" |

| "ESSOLUBE" (Esso Petroleum Co. Ltd.) | "Essolube" 30 | "Essolube" 20 | "Essolube" 10 | "Esso" Expee Compound 90 | "Esso" Expee Compound 80 | "Esso" Bearing Grease | "Esso" Chassis Lubricant | "Esso" Chassis Lubricant | "Essolube" 20 |

| "MOBILOIL" (Vacuum Oil Co, Ltd.) | Mobiloil "A" | Mobiloil "Artic" | Mobiloil "Artic Special" | Mobilube "G.X." 90 | Mobilube "G.X." 80 | Mobilgrease No. 5 | Mobilgrease No. 2 or 4 | Mobilgrease No. 2 or 4 | Mobiloil "Artic" |

36

LUBRICATION (Engine)

Oil Pressures • Engine Drain Plug

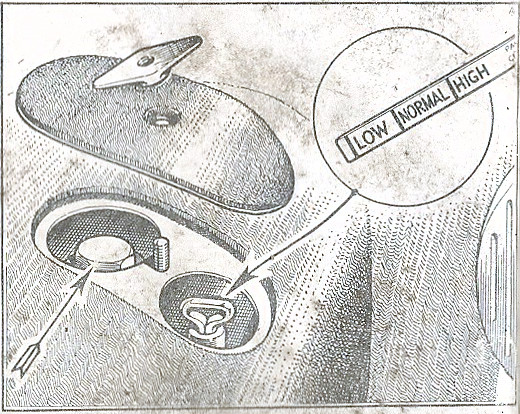

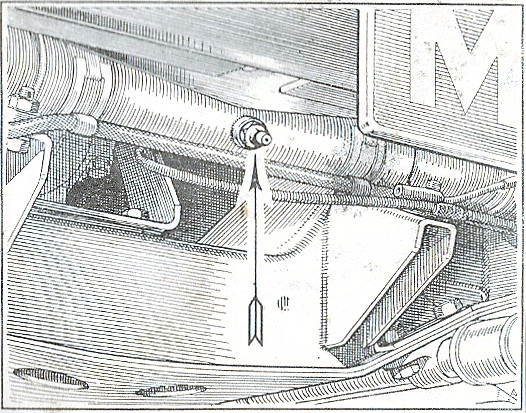

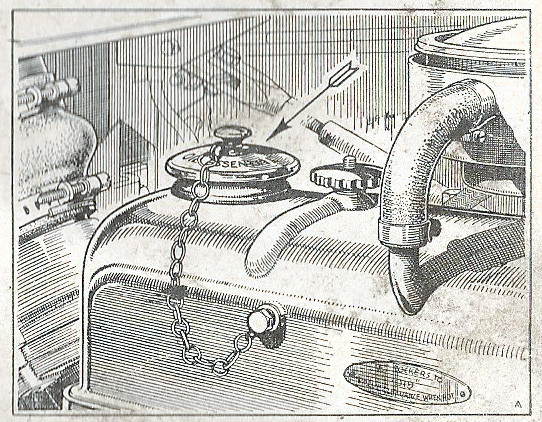

Replenishing Engine Sump

Engine lubrication

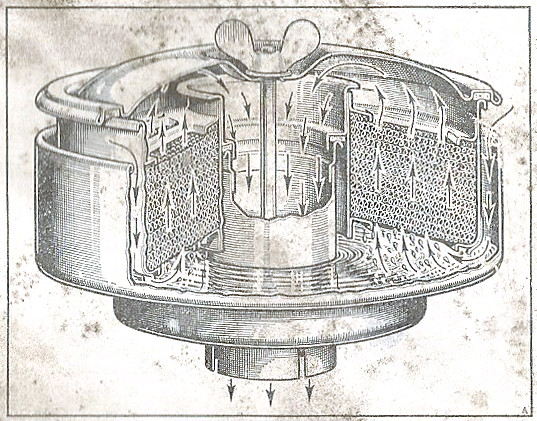

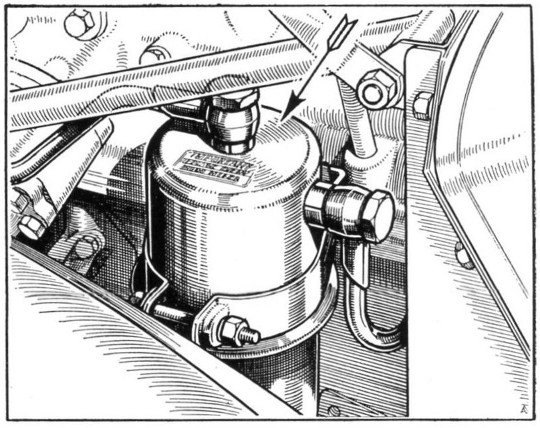

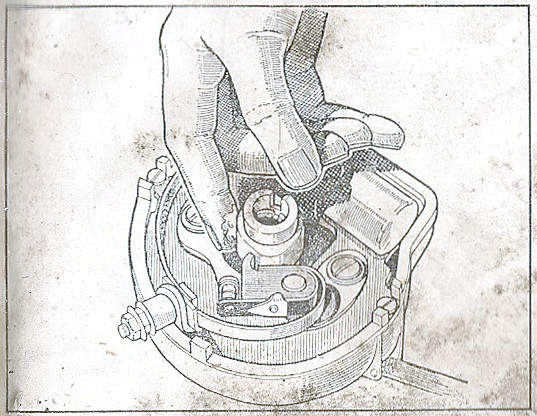

The oil supply is carried in the sump below the cylinder block and is drawn through a gauze

internal filter and renewable external filter before circulation through the engine. It will be found on first

starting the engine from cold that a high-pressure reading will be obtained on the oil gauge. This will

gradually drop as the engine warms up and the oil becomes more fluid, until a normal pressure of approximately

25 to 40 lb./sq. in., (1.75 to 2.8 kg./cm.2) is indicated. Avoid racing the engine when first starting up

while the oil is cold. On the other hand, do not let it idle too slowly. It should be allowed to rotate at

approximately 1,000 r.p.m., an engine speed equivalent to 15 m.p.h. (24 k.p.h.) in top gear.

Instructions for checking the quantity of oil in the sump and replenishment are given on

page 6.

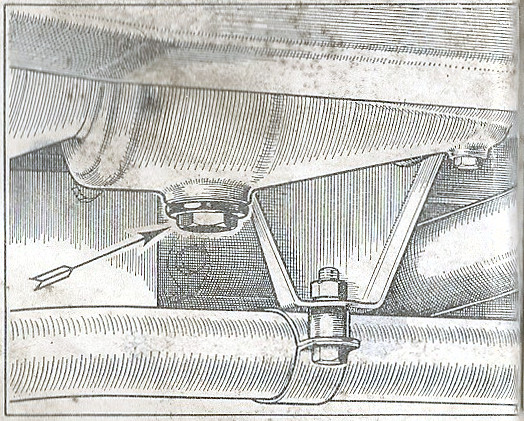

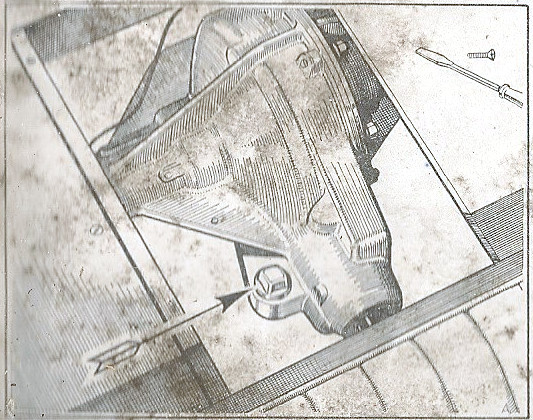

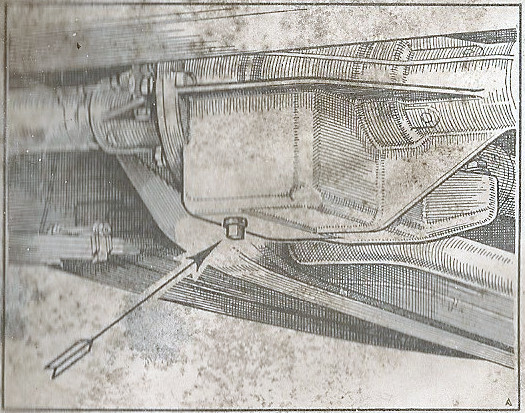

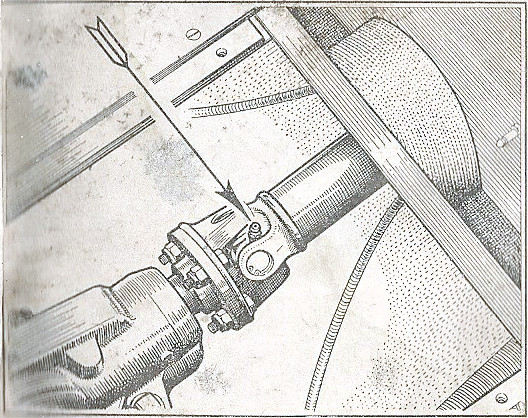

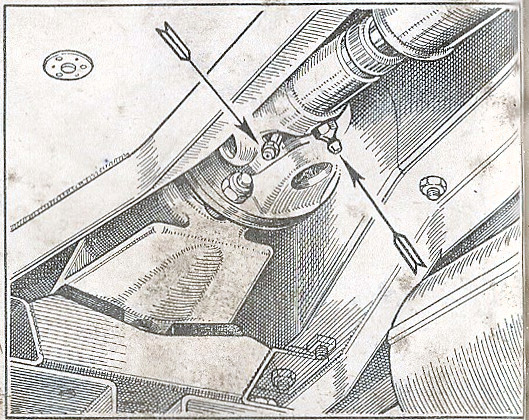

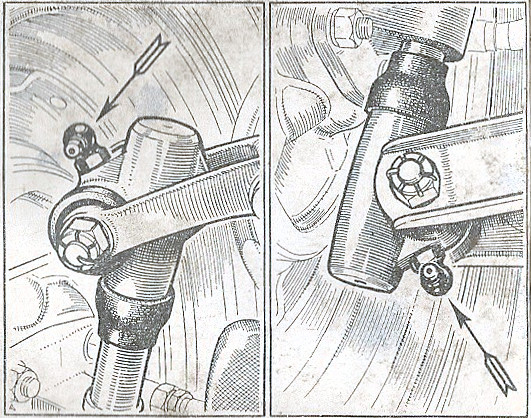

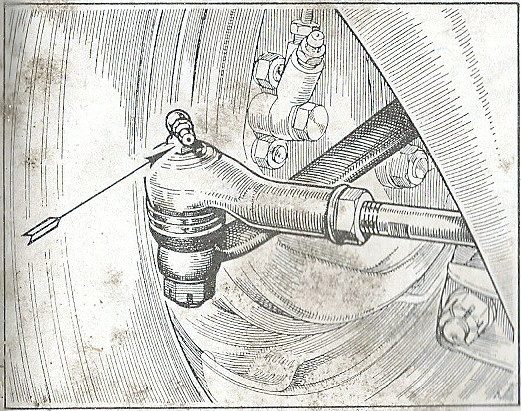

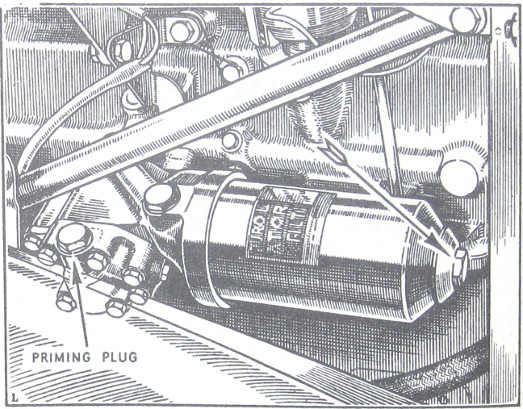

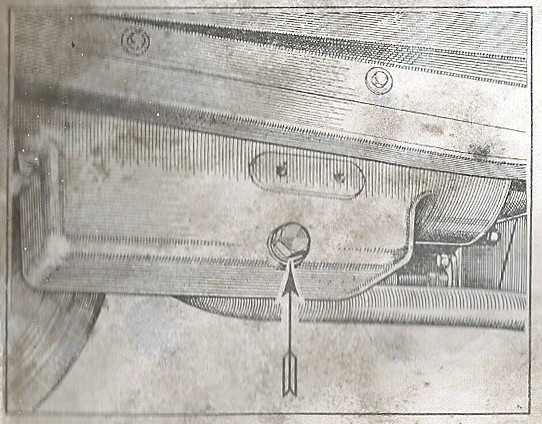

Draining the sump (A)

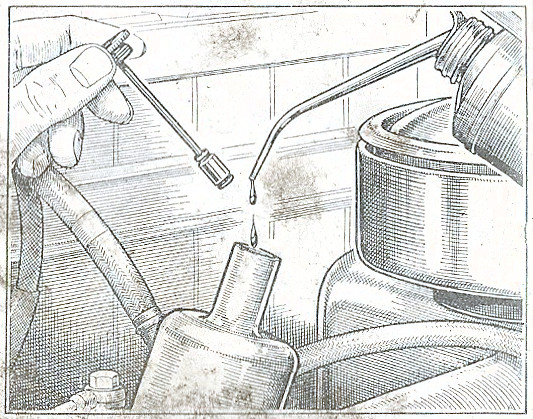

We recommend that when the car has completed the first 500 miles (800 km.) the oil in the sump

should be drained to clear the sump from any impurities that may have accumulated during the initial

running-in period. After the first 500 miles (800 km.) we recommend that the sump should be drained

every 3,000 miles (5000 km.) and refilled with the recommended lubricant. This operation is best

carried out immediately the car returns from a journey, while the oil is still warm and fluid.

On the left side of the engine will be found a brass drain plug. Removal of this plug will release the

contents of the sump. After carefully cleaning the drain plug, which will probably have an accumulation

of dirt in its hollow centre, it should be replaced and screwed up tightly. When the sump has been

drained completely, approximately 1⅛ gallons (5.1 litres) are required to fill it.

37