|

End of Menu Items |

Safety WiringEver wondered about how to use safety wire? Here are two articles to help explain the technique involved. The first article is by an unknown author and from an unknown source (unfortunately), and the second is by the late Bill Phy who was a member of the Vintage MG Club of Southern California. The articles were provided by Dave DuBois, Washington, USA.

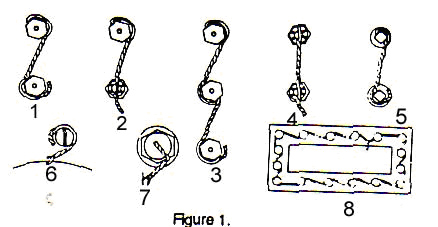

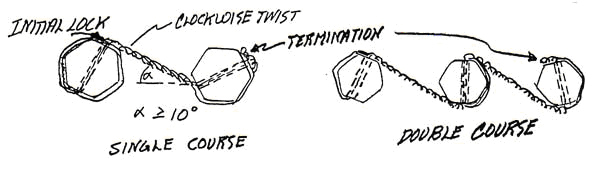

Article #1 Author and source unknown.Threaded fasteners are Safety Wired by the single-wire or double-twist method. While the Single-Wire method may be used in a closely spaced closed geometrical pattern, on parts in electrical systems and in places difficult to reach, Double-Twist is the most common method of Safety Wiring. Figure 1 illustrates various methods commonly used in Safety Wiring nuts, bolts and screws. Observing this illustration, it will be noted that: A. Examples 1, 2 and 5 show the proper method of Safety Wiring bolts, screws, square-head plugs and similar parts when wired in pairs. B. Example 3 shows components wired in series. C. Example 4 shows the proper method of wiring castellated nuts and studs. (Note that there is no loop around the nut.) D. Examples 6 and 7 show a single-threaded component wired to a housing or lug. E. Example 8 shows several components in a closely spaced closed geometrical pattern, using the Single-Wire method.

Article #2, Bill Phy. On Tying It All Together Safety Wiring 101

|