|

End of Menu Items |

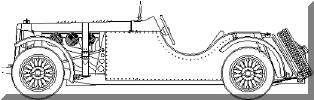

YT 4608 - "Blue Streak" special

The Building of "Brum" a YA / Blue Streak Special

Chassis Rear | |||

Having made the conceptual decision to build, not a replica K3 but the K3 that MG might have built in the 1950's I was then faced with the all the technical decisions related to building such a vehicle. I wanted to build the car with as many MG components as possible to give it the right look and feel.

I wanted an engine of the era that would look and sound right and that had some connection to MG, was tuneable, reliable and readily available. I had previously built a TD special using a 1622cc B-Series engine from an Australian built Morris Major Elite coupled to a ZA Magnette gearbox and found the 1622 ideal as a lot of tuning options were available from MGA and MGB sources. The engine I finally chose was the Australian developed "Blue Streak Six" that was fitted to the Austin Freeway and Wolseley 24/80. This engine in original form at 2433cc produced 80HP at 4000 RPM but was easily tuneable to twice that power.

I then measured the chassis, locating all mounting points and structural members and created a CAD model of the chassis using AutoCAD software on my PC. I also modelled the engine and gearbox to correctly locate them in the chassis and used the AutoCAD model to recut a late model Mk. II MGB rear cross-member to fit into the chassis after cutting the original gearbox cross member from between the chassis rails leaving the outrigger sections on which to mount the front of the body tub. Having measured the critical anthropometric dimensions from my TD I then transferred seat locations, pedal pivot centres, dashboard height, steering wheel centre etc. to the model and then spent weeks sketching body designs around these fixed dimensions.

I toyed with timber framed and metal framed bodywork in a variety of styles and detailed the critical areas in section and elevation to determine the best fabrication method. My lack of coach building skills and a tight budget meant I had to come up with a method that looked good and that I could build myself with only a small coach-building budget. I decided to weld up a tubular aluminium frame and rivet aluminium panel work to the frame using exposed mushroom head rivets. This meant that I could clad the body in sections of panelling which allowed for most of the panel work to be cut and formed at the local sheet metal shop and that I could, with some time and care, fit and rivet to the tub frame myself. Sick of scuttle shake I did not put in doors and also fitted a tubular space frame brace to the underside of the scuttle behind the half-inch plywood dash panel.

The curved sections of square tube forming the upper and lower extremities of the tub were bent to the CAD model from a data file provided to a local tube bending company. The upper rails, also bent in the horizontal plane to match the lower rails were cut and welded over a timber former to ensure that the side panels were vertical over the full curve of the body. 3mm aluminium plate firewall and firewall brackets are bolted to the chassis via welded on steel cleats with Stainless steel Bolts. A similar 3mm-plate panel runs behind the seats in the location that the rear body brace occupies in a T-Type. Half-inch plywood floors screwed into tapped holes in the aluminium angles forming the bottom rails of the tub to complete the body, with a battery box behind the passenger seat and a toolbox behind the drivers seat just ahead of the rear axle. To maintain the right radius on the rear corners of the body I rolled a wide section of 3mm plate and set it to the correct angle for the rear slope of the tub and scribed all the top and bottom tub rails into it and welded them in place.

A steel replica grille shell from a TD2000 was used with a stainless steel mesh insert and fitted to the chassis over a custom made 85mm deep aluminium radiator. This radiator was custom built with inlet and outlet in the correct position for the B Series motor and concealed filler with a 13.5 pound cap but was mounted with MG YA rubbers and bolts to a new MG TD style radiator mount located over the Triumph 2500 steering rack. The steering rack was chosen as the pinion is set further out than an MG one and allowed for the extra long steering column, fabricated from 2 MGB steering columns fitted back to back to clear the engine. The rack is mounted to the original YA brackets using a Triumph 2500 clamp on one side and a Rover 2000 one on the other with the tie rods shortened to fit the MG track.

An all synchro Mk. II MGB gearbox with the input shaft machined down to fit the spigot bearing was mated up to a modified Mk. I backing plate and the heavy Wolseley flywheel lightened to 21 pounds was fitted with a heavy duty Wolseley diaphragm clutch and MGB Mk. II driven plate. In keeping with engine installation practice of the 1950's I fitted an XPAG style front engine mount bracket with an MG TD front engine mount to the front engine plate. The rear gearbox mounts are MGB and the engine is stabilised by a rose-jointed stabiliser made from heavy wall hydraulic tubing fitted to a bracket at the triangulation point of the firewall, firewall brackets and tubular firewall braces. A heavy aluminium channel is bolted across the back of the fire wall connecting these two triangulation points around the engine and to the space frame under the scuttle. This allows the body to flex in the same direction as the chassis without allowing scuttle shake or lateral engine movement.

The rear axle is also from a Wolseley 24/80 using a beefed up cast iron version of an MGA diff centre with much heavier axles. This axle fitted to the re-set YA rear springs and the shock absorber arm mounts lined up exactly with the ends of the shocker arms. A shortened MG TD drive shaft connects the gearbox with the rear axle and a ZA handbrake level fits to the Wolseley handbrake cable, which is the same as an MGB. MGA rear wheel splined hubs are bolted to the rear hubs using the Wolseley wheel studs through MGA brake drums. The front suspension is MGB with heavier rate springs and a standard B sway bar and disk brakes which all bolt straight up to the YA cross member with no modification. New Dunlop 60 spoke 15 x 4.5-inch wire wheels fitted with Vredestein classic sport radials provides connection with the road. The spare wheel bracket is a cut down MG TD one over a custom-made aluminium 72 litre fuel tank.

Engine modifications included overboring to 2498cc and fitting of flat topped High compression MGA pistons, high lift cam grind and some serious headwork. Three 1.5 inch SU carburettors fitted to two MGA inlet manifolds cut and welded together are used with the original Blue Streak exhaust manifold which has a 2-inch diameter outlet ideally suited to a 2 inch straight through exhaust with a small resonator fitted to meet registration requirements. A full blueprint and balance followed by a dyno tune at the local E-Type tuning specialist has produced impressive power and torque.

The braking system is a combination of MGA Mk. II master cylinder fitted with inverted LHD MGB pedals, using MGB pivots mounted on a new bracket fitted 6 inches further back than the original pedal box and an MG TD hydraulic brake light switch fitted in the front brake line near the engine so as to use a common wiring loom without any wires under the car.

The main front cycle guard brackets are after market MG TC ones modelled on J Type brackets with custom-cast aluminium headlight brackets bolted to them. I made patterns for a number of other castings for the rear mudguards, and corner trims to match the capping extrusion fitted to the top of the body frame to cover the edge of the aluminium panel work. A coachbuilder fabricated the scuttle, mudguards and bonnet whish is fitted with a stainless steel bus door piano hinge. Seats framed in aluminium similar in shape to K3 seats were professionally trimmed in blue to match the internal trim panels that I made to finish the interior.

On its first competition outing, whilst still running in the engine I recorded 30.9 seconds in the Victorian Classic and Historic hill-climb at Rob Roy hill climb finishing in second place. A very good showing in the MGCC annual concourse followed this with an enormous amount of positive interest in the car at both events. I have now completed 2000km of trouble free driving and apart from lifting the front of the car half an inch to clear the tyre from the cycle guards I have had to do nothing but change the oil. The car is a delight to drive and is the ideal combination of classic style and modern driveability, with enough performance to easily match an MGBV8.

MG Y Type Blue Streak Special "Brum"

Chassis |

1950 MG YA Sedan |

Engine |

2433 cc Wolseley 24/80 Mk II, Bored 0.040" to 2498cc |

Flywheel Lightened to 21Pounds (originally 28.5) | |

Pistons JP0511 Pistons MGA 1622 Flat-top +0.040" with 11/16 gudgeons | |

Piston Rings JP FY511 040 (+0.040") | |

Big Ends MGA 1500 (-0.010) | |

Mains BMC 3M2254 (-0.020") | |

Cam Bearings MGB Durabond EBC 4306C3db (Bearings #3 and #4). Bearings #1 and #2 Re-used original Bearings | |

Camshaft Wade 104-grind .282" Cam lift | |

Inlet manifold 2 x MG ZA Magnette (end to end) Port matched and polished | |

Exhaust manifold Wolseley 24/80 with warm up plate removed | |

Carburettors 3 x 1.5 inch S.U. (Wolseley 6-90 choke assemblies) Ram Tubes | |

Accelerator cable Shortened MGB | |

Engine Back Plate MGB Mk II (Modified... relocated 24/80 Starter motor) | |

Front Plate Wolseley 24/80 with Custom made Engine Mount Bracket | |

Front Engine Mount MG TD/MG Y Type | |

Gearbox |

Mk II MGB (Non overdrive) reduced input shaft (To suit Mk 1 Spigot bearing) |

Gearbox X-Member MGB Mk II (US Spec. with long stabilizer) welded into chassis | |

Gearbox Mounts MGB Mk II | |

Clutch |

Pressure plate Wolseley 24/80 diaphragm type |

Driven plate MGB Mk II | |

Slave Cylinder — MGB Mk II | |

Tail shaft |

MG TD (Shortened) |

Front Universal MGB | |

Rear Universal Wolseley 24/80 | |

Engine Stabilizer |

TS 27 Hydraulic pipe, 12.7 OD x 1.6 wall, 38 UNF HT Bolts to3/8" UNF rod ends Boston HF-6C, |

Engine Fan |

Original Wolseley 24/80 metal fan |

Wheels / Suspension |

Lower Wishbones - MGB Mk. II |

King Pins - MGB | |

Steering Arms - MGB | |

Front Hubs - MGB | |

Front Springs - MGB (Competition) | |

Sway Bar - MGB Mk. II | |

Panhard Rod — MG Y (Rose jointed) | |

Tyres Vredestein Sport 165 x 15 | |

Bushes All Polyurethane (Except Panhard rod - chassis end is rubber) | |

Front Shockers MG Y Type (Girling) | |

Rear Shockers Morris Minor 3/8" UNF rod ends | |

Wolseley-24/80 shocker links | |

Rear Axle |

Wolseley 24/80 3.9:1 |

Rear Springs |

MG Y (heavy duty, Flatter profile) |

Rear Hubs |

MGA |

Axle Bushes |

Polyurethane, Pedders EP-254 Shackle Bush |

Steering Rack |

Triumph 2500 (Non Power Steering) Tie rods shortened, heat-treated and tuftrided Tie rod Ends Late model Nissan Pulsar |

Wheels |

Dunlop XW452M 15" x 4.5 — 60 Spoke Painted |

Steering Column |

Upper section — MGB Mk II |

Lower section — Custom made, MGB/ | |

Upper universal MGB | |

Lower universal Triumph 2500 | |

Rack mounting rubbers Triumph 2500 | |

R.H. rack clamp triumph 2500 | |

L.H. rack clamp Rover 2000 | |

Brakes |

Front Discs - MGB |

Front Calipers - MGB | |

Disc pads MGB Standard | |

Rear Drums - Wolseley 24/80 | |

Rear cylinders Wolseley 24/80 Stainless steel sleeved | |

Master Cylinder - MGA 1600 Stainless steel sleeved | |

Brake Pedals - MGB (LH Drive Inverted) | |

Pedal Shaft, Bushes, Spacers - MGB | |

Brake Light Switch - MG TD | |

Flexible Lines - MG ZA | |

Handbrake — MG Y/ Z Magnette | |

Handbrake cable Wolseley 24/80 (Shortened / re-swaged) | |

Chassis |

Radiator 85mm Core Alloy Custom radiator |

Radiator Cap Standard 13lb Wolseley 24/80 | |

Top Hose 275mm x 32 I.D. Universal Radiator Hose | |

Bottom Hose 400mm x 32 I.D. Universal Radiator Hose | |

Rack foundations Original MG Y with transverse braces welded to X-Member | |

Body |

Spare Wheel Carrier - MG TD |

Bodywork — Custom aluminum | |

Cycle Guards | |

Riveted panel work | |

Grille Shell TD 2000 | |

Grille Badge MG TF | |

Dummy Radiator Cap MG ZA Magnette | |

Aero screens Brooklands | |

Rear view mirror MGB Mk I (modified mounting pin) | |

External Mirrors Tex. R1 Stem head L & R | |

Grab Handle MG Prewar Replica | |

Electrical |

Alternator MGB Mk II |

Starter Motor Torque performance products geared reduction unit (MGB) | |

Headlights MG Y (Chrome Plated) | |

Headlight Rims Lucas 7" reducing rims | |

Headlight Inserts AUTOPAL — From Classic & Vintage Bulbs - S.A. | |

Headlight Globes Halogen H4-45-12-60/55 (P45t Base) | |

Tail Lights Lucas D lamp (Morris Truck) | |

Horn switch MGA (Relay operated horn) | |

Horn SVC Vintage horn. (Small Chrome type) | |

Fuse Block Hella | |

Cut off Switch Hella | |

Fuel Pump Pierberg | |

Tachometer Jaguar 240 | |

Temp/Oil Speco | |

Sender Units Speco | |

Light switches Hella Marine | |

Starter Switch Hella Marine |

The Blue Streak Engine

A number of the Australian developed Blue streak 6 engines were sent to Abingdon and fitted into prototype MGC's as part of the MGC development program, only to be replaced by a bigger (and much heavier) engine in a desire to satisfy the US markets appetite for more cubic inches. The engine is a 6 cylinder stretch of the Australian 1622 cc B series engine fitted to the Morris Major Elite and Morris Oxford.

The Australian 1622 retained the 1500cc Crankshaft with the bigger main bearings than the UK 1622 motor and BMC Australia increased the size of the mains again for the 6 cylinder motor. In the standard low compression model as used in the Wolseley 24/80 and Austin Freeway they are very smooth with good torque, but are easily converted to High Compression MG spec.