|

End of Menu Items |

Y 6737 — An MG Y Four Door Tourer

The history of the Four Door Y Type Tourer by Matthew Crawford

Click on the thumbnails below to open the full sized pictures. | ||

Y 6737 before |  Y 6737 during |  Y 6737 after |

MG Y 6737 started life as a four door sedan built in 1951. It was owned by Philip White, a Sydney solicitor, who engaged a panel beater-painter from the central coast of East Australia to carry out minor body repairs and a respray of the car. Unfortunately, on its travels up the coast the car blew off the transport vehicle landing on its right side and roof, on the notoriously windy Mooney-Mooney Bridge. This severely damaged the superstructure. We happened to be travelling in the opposite direction at the time, and saw the car sliding along the bridge whilst lying on its right side.

The next time I saw the car was in 2006 at my regular auto body shop, where the car was undergoing rust repairs. The bottom sills of the rear doors were being replaced. A refurbished engine had been fitted with, the original engine being replaced by XPAG/SC/16551 from Y 6774, another one of Philip White’s cars. I must say the car caught my eye at the time, as something that I would like to acquire at some stage in the future, as novel project. In the mean-time I acquired a YT as well as two unloved YA’s from the southern suburbs of Sydney. This was at the instigation Alf Luckman, who had been The MGCC Sydney’s long serving registrar for Y Types. The YA’s had been out in the weather for some thirty years and although they provided a useful source of mechanical parts, however most of the body panels were not.

As it would have been uneconomic to repair the four-door sedan of Phillips White’s to original condition, Alf convinced him to convert the car to a four-door convertible Y type. Philip enlisted the help of his panel beater & welder brother and together they cut the roof off and modified the centre pillars to support the doors. As the front screen frame was also distorted it was also removed and a YT windscreen fitted.

Just after I acquired the YT, the Four Door Tourer became available at an attractive price, as it was clear the Philip was not going to be able to complete the project due to illness. The car came with significant history, both written and in photographs supplied by his wife Kaye. Again Alf asked me to purchase the car, as he could see that it would be completed. The car was purchased in October 2009, and squeezed into the already overflowing workshop. My youngest daughter had hoped it would be ready for her wedding day, but alas she had to make do with our YA and YT and a loan YA from the club to accommodate the bridesmaids.

The complexities of getting this project off the ground were somewhat more than restoring a vehicle to its original condition. We needed to engage the services of an engineer that would supervise the project and dictate the modifications that were required to the body structure to allow it to comply with the Roads and Traffic Authority requirements.

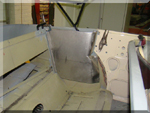

It soon became clear that the body of the car needed to be reinforced such that it would have similar strength to that of a unitary constructed car, despite sitting on a chassis. A fully welded steel floor was required, however, unfortunately the chassis had been constructed with a solid beam supporting the rear of the gearbox. This then meant that the gearbox tunnel, and the removable sections of the floor/fire wall needed additional bracing to increase strength and allow removal, to allow gearbox and engine removal. Cross bracing was placed in the scuttle and across the rear seat back. The junction of the rear seat platform and body structure was strengthened at the rear door by the addition of welded steel pockets to house the hood bows. The area below the seat platform next to the rear doors was fitted with little lockable cabinets, welded between the floor and seat platform where the kickboard had been. The doors required strengthening where the upper hinges were placed in their new position. The brackets to reinforce the hinge mechanisms inside the doors were sourced from the doors of the Kirrawee cars. Additional strengthening was placed in all doors to prevent side intrusion.

A “Taxi bar” was placed between the door pillars to strengthen the body from side impact intrusion, and to act as anchor points for the seatbelts. Retractor seat belts were needed as were head rests. The mountings for the rear retractor belts were place in the boot, and those for the front seats were placed under the floor in sealed housings. Both sets of belts had “eyes” for the belts to slide through at shoulder height. The rear “eyes” were secured to the reinforced seat back and the front ones to the “taxi bar”.

A recess was fashioned behind the rear seat to accept the hood when folded down. The boot space was modified by raising the floor to accept a standard 15” X 4.5” 60 spoke MGA wheel with a 165X 15” tyre, i.e. the same as those on the other wheels. To gain access to this tyre the boot floor needs to be removed. When the body and chassis were assembled in their complete configuration, a deformity test needed. A number of heavy individuals totalling 400 kg, sitting inside the car, were required for the measurement of any deflection of the body and chassis structure. Deflection was measured at less than 2 millimetres.

Mechanical modifications included the addition of a supercharger a modified Toyota CS 14, a Toyota Celica five speed gearbox, a steel crankshaft, slightly modified camshaft, and the engine was balanced, TF Valves were inserted and the head was ported and polished. Front power assisted MGA disc brakes were fitted as well as a Morris Minor 4.55 differential centre. A high flow fuel pump with a pressure regulator was fitted to supply the 1-3/4 inch HS6 SU Carburettor and Supercharger. To cope with the increased power being delivered to the rear wheels, the rear 3/8 inch wheel studs have been increased in diameter to 7/16 inch MGA type. To provide a perfectly flat surface for the Austin Healy hubs to bolt to the rear brake drums these have been replaced with cast aluminium Nissan 180B drums. All of this required drilling the hubs, half shafts and the brake drums, to provide a much more solid base for attachment of the rear wheels. Ignition is provided by a 123 electronic distributor.

To finish the front scuttle it was modified to look like a T type. The original dash was modified to accept a TF instrument cluster that was turned upside down and modified to fit around the steering column. This housed the speedometer, tachometer and the oil pressure, ammeter and fuel gauge. A water temperature gauge and boost gauge were also fitted into the centre of the dash between the instrument cluster and the glove box. Laminated burr walnut was applied to the front dash and the wood pieces covering the tops of the doors. Between the two front seats, a cocktail cabinet was constructed, also covered in burr walnut. The area above the modified dashboard has been covered with laminated burr walnut. Side curtains have been made from modified YT side curtain frames, fitted into stainless steel tubes mounted through the wood on top of the doors into the door frames, and held in place by modified MGA knurled side curtain nuts.

As the hood is fitted further back than in a YT, the hood frame needed to be lengthened to reach the front screen, via a sliding mechanism such that it can be folded back to its original size to fit in the recess behind the back seat.

Following completion of the body work, the car was transported to the trimmers to be upholstered in biscuit coloured leather with red piping for the seats, a maroon soft top with carpets and tonneaus.

LED lights are fitted where possible to brighten up the dim light provided by the original Lucas electricals, as well as high and low tone Lucas horns.

Following completion of the car, it required sign off by the engineer with a six page document listing all of the modifications made as well as its new weight at 1040 kg an increase of 49 kg from its original weight.

The car has had two outings, the first to Annual National MG Car Club Meeting in Warners Bay NSW, a run of 600 km. The second run was to Gympie in Queensland for the MGY 75th Anniversary meeting, a run of 1600 km. The car performs well and keeps up with traffic on the freeway at 110 km/hr with the engine doing 3,500 RPM. On the way home from Gympie it suffered a regulator failure, which has subsequently been resolved.

A resplendent Y 6737 - MG Y (four door) Tourer | ||

Accident damaged Y 6737 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|