|

End of Menu Items |

| John James - replacement for XPAG cork side cover gaskets |

The Problem

When an engine is running, petrol vapour and exhaust gases leak past the piston rings. These gases contaminate the oil; one reason it turns black. They also increase the pressure in the sump. On modern cars there is a valve arrangement that connects the sump to the inlet manifold. When driving on part throttle, there is a partial vacuum in the inlet manifold. As this is connected to the sump, there is also a partial vacuum in the sump. Any gases escaping past the piston rings are sucked back into the inlet manifold rather than pressurising the sump. The partial vacuum in the sump also stops the oil from leaking out.

The original gasket

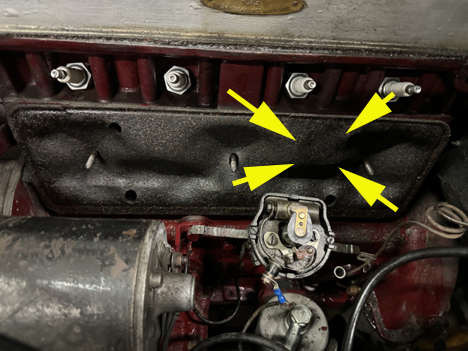

The XPAG does not have this arrangement. The sump is vented by a breather pipe on the tappet cover. There is a large gasket behind the tappet cover. This stops oil from flowing directly into the breather pipe. The cover is dished to provide a space between the gasket and breather pipe for the gases to vent.

Unfortunately, the gasket distorts, especially the earlier ones which are quite thin. The breather pipe has a ridge on the inside to prevent it getting blocked by the gasket. But…..a distorted gasket can significantly reduce the gas flow, allowing the pressure in the sump to rise. This in turn then can force oil past the front and rear engine seals contributing to, or exacerbating, the famous XPAG oil leaks.

A used gasket. Note the distortion. You can see the outward distortion where the vent pipe is located on the right hand end of the gasket.

The Solution

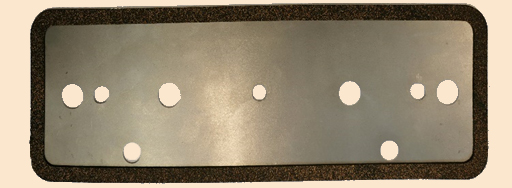

Introduced by Paul Ireland back in December 2020 the replacement consists of a thin steel plate with nitrile bonded cork gaskets. Unlike the original cork sheet gasket, the steel plate will not bend or distort and then cause excess pressure build up.

The replacement gasket - note the extra holes!

The original gaskets have 4 holes near the edge. The bottom two are to let any oil that gets between the gasket cover and gasket drain out. The smaller middle three holes are for the mounting studs. The larger four holes allow exhaust gas to pass through to the breather tube. These holes are very close to the edge where there is less space between the cover and gasket. Any distortion of the gasket can easily block them. There is a second problem with this design. The holes at the top will let oil pass through. One is close to the breather tube. There is a risk of oil being blown down the breather tube.

The two holes at the top have been replaced by four larger holes along the centre line of the tappet cover. There are thin cork gaskets around the inside and outside edge of the metal gasket to provide the seal. A metal gasket will not distort, guaranteeing an open channel between the sump and breather tube.

Fitting is very simple and full instructions can be downloaded here.

As of 2024, the cost for these is £17.00, plus postage at cost. If you would like a set, please send an email to jj(at)ttypes.org (Please substitute @ for (at)) and I will let you have postage costs and payment options.

Does it work?/Customer feedback

While this will not eliminate all oil leaks ftom the front and rear lip seals, it should reduce them. Moreover, it will not need replacing!

Just one of many feedback comments I have received for these is:

“I just wanted to let you know that having now fitted and driven the TC a bit since fitting the new steel gasket plate, that it has very noticeably reduced the amount of oil being pushed through the rear main seal, into my catch tray,

This had previously become quite bad, as it would often manage to throw a small amount onto the exhaust, after a bit of cornering. When we were out last, I noticed that this too had reduced significantly.”

The profits?

The profit on these kits has helps in a small way to bolster Paul Ireland’s funds from the royalties of his book Classic Engines. Modern Fuel https://classicenginesmodernfuel.org.uk which he has used on his project to help with children’s education in a couple of schools in Tanzania.